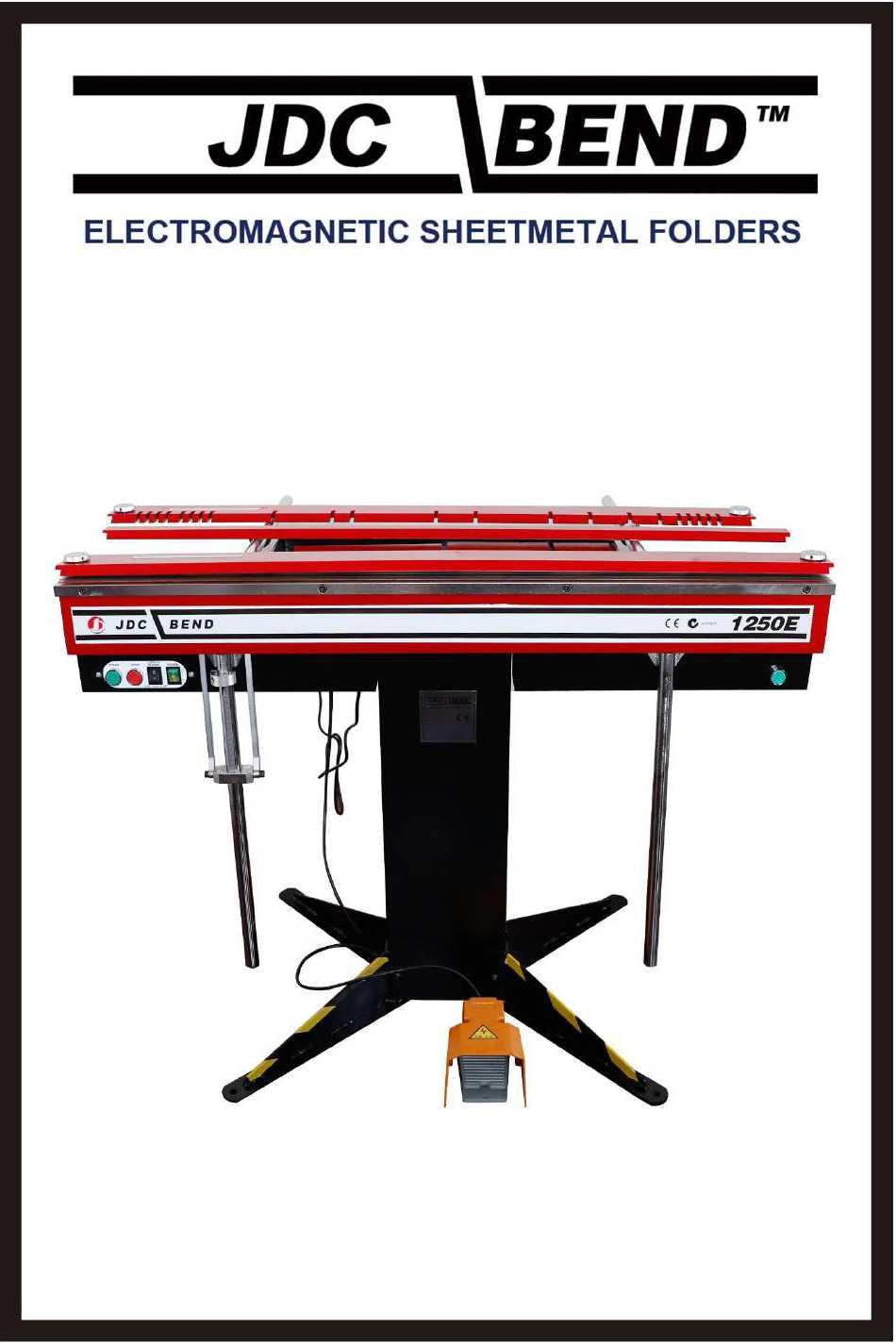

JDCELECTROMAGNETIC SHEETMETAL FOLDERS

JDC BEND • MANHAJAR MAI AMFANI

domin

MISALI 650E, 1000E& 1250E

Abubuwan da ke ciki

GABATARWA

MAJALIYYA

BAYANI

TAKARDAR ODAR 6AD0 ZAMA AIKATA

AMFANI DA JDCBEND

BASIC AIKI

KAYAN WUTA WUTA

RUWAN LABA (HEM)

GANGAR JIKI

YIN GWAJIN GWAJI

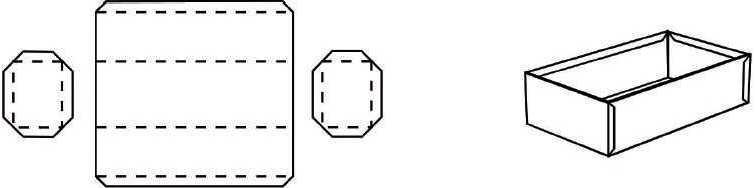

Akwatuna (GAJANIN TSARA)

TURAS (SLOTTED CLMPBARS)

AMFANI DA TSAFIYA

JDC GABATARWA

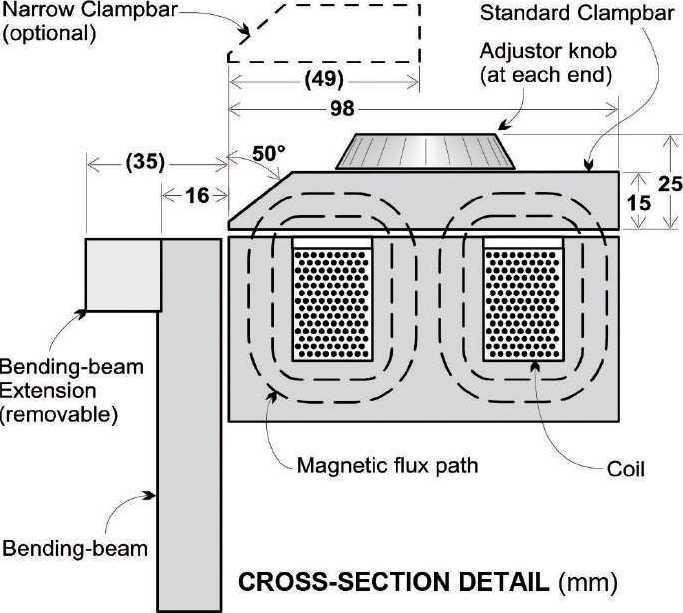

JdcbendNa'urar lankwasawa sheetmetal ne mai matuƙar m da sauki don amfani da inji don lankwasa kowane irin sheetmetal kamar aluminum, cop-per, karfe, da bakin karfe.

The electromagnetic clamping tsarinyana ba da ƙarin 'yanci don samar da aikin aiki zuwa sifofi masu rikitarwa.Yana da sauƙi don samar da ƙananan ƙananan channels, rufaffiyar sassan, da akwatuna masu zurfi waɗanda suke da wuya ko ba za su yiwu ba akan na'ura ta al'ada.

Tsarin hinging na musammanamfani da katako mai lanƙwasawa yana ba da cikakkiyar buɗaɗɗen inji don haka yana haɓaka ƙarfinsa sosai.Ƙirar ginshiƙi guda ɗaya kuma yana ba da gudummawa ga haɓakar na'ura ta hanyar samar da tasirin "hannu mai kyauta" a ƙarshen na'ura.

Sauƙin amfaniyana gudana daga ikon yatsa na ƙwanƙwasa da ƙaddamarwa, sauƙi da daidaiton daidaitawar lanƙwasa, da daidaitawa ta atomatik don kauri na sheetmetal.

Matsala mai hannu biyuyana ba da aminci ga mai aiki.

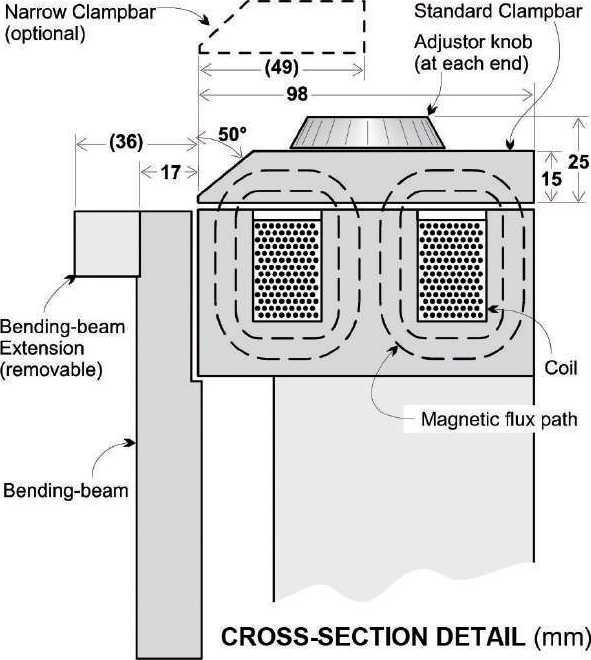

AsaliYin amfani da ƙwanƙwasa maganadisu yana nufin cewa ana ɗaukar nauyin lanƙwasa daidai a wurin da aka samar da su;Ba dole ba ne a tura sojoji zuwa tsarin tallafi a ƙarshen na'ura.Wannan bi da bi yana nufin cewa memba mai matsawa baya buƙatar kowane babban tsari don haka ana iya sanya shi ƙarami da ƙarancin hanawa.(An ƙayyade kauri na clampbar kawai ta hanyar buƙatun sa don ɗaukar isassun kwararar maganadisu ba ta hanyar la'akari da tsarin kwata-kwata ba).

Makullin mahalli na musamman mara tsakiyaan ƙera su musamman don Jdcbend, kuma ana rarraba su tare da tsawon katako mai lanƙwasa don haka, kamar ƙugiya, ɗaukar nauyin lanƙwasa kusa da inda aka samar da su.

Haɗin tasirin damaganadisu clampingtare da na musammanhinges maras tsakiyayana nufin cewa Jdcbend yana da ƙima sosai, ajiyar sararin samaniya, inji tare da ma'aunin ƙarfi-zuwa nauyi.

Don samun mafi kyawun injin ku,don Allah a karanta wannan littafin, musamman sashen mai suna AMFANI DA JDCBEND.Da fatan za a dawo da RAJIN WAR-RANTY saboda wannan zai sauƙaƙa kowane da'awar ƙarƙashin garanti kuma yana ba masana'anta rikodin adireshin ku wanda ke sauƙaƙe sanar da abokan ciniki duk wani ci gaba wanda zai amfane su.

MAJALISAR...

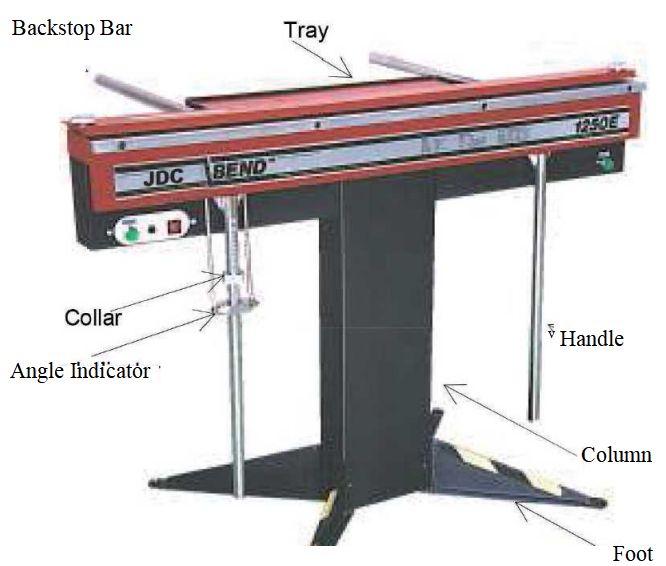

BAYANIN MAJALISAR

1.Buɗe ginshiƙi da ƙafafu kuma gano fakitin fakiti da maɓallin Allen 6 mm.

2.Haɗa ƙafafu zuwa ginshiƙi.Ƙafafun biyu tare da tef ɗin aminci na baki da rawaya yakamata su nuna gaba daga ginshiƙi.(Fuskar gaban ginshiƙi ita ce gefe ba tare da haɗin gwiwa a ciki ba.)

Yi amfani da maɓalli na MIO x 16 don haɗa ƙafafu.

3.Model 650E da 1000E: Haɗa farantin ƙafa a ƙarƙashin tukwici na ƙafafun gaba.Yi amfani da screws biyu na MIO x 16 tare da wanki.Daidaita ramukan dunƙule za a sauƙaƙe idan an bar sukulan hawa ƙafar a kwance har sai bayan an haɗa farantin ƙafar.Za a iya daidaita sukulan hular hular M8 x 20 a cikin ƙafar baya don daidaita na'ura da dacewa da kowane rashin daidaituwa a cikin bene.

Model 1250E: Ba a samar da farantin ƙafa da wannan na'ura;dole ne a kulle shi zuwa kasa a gaban ƙafafu na gaba.

4.With tare da taimakon mataimaki a hankali sanya na'urar Jdcbend a kan tsayawar kuma ya kulla shi da M8 x 16 cap-head screws.

Samfura 650E & 1000E: Tabbatar da jagorar wayoyi da mai haɗawa ƙasa zuwa cikin ginshiƙi yayin da ake saukar da injin akan tsayawar.

5.Model 650E & 1000E: Cire sashin shiga wutar lantarki na baya kuma toshe tare da mahaɗin 3-pin.Wannan yana haɗa electromagnet a jikin injin zuwa naúrar lantarki a cikin ginshiƙi.Sauya panel.Model 1250E: Haɗa faifan kebul na mains zuwa baya na ginshiƙi tare da dunƙule kwanon kwanon M6 x 10.

6.Model 650E: Haɗa ɓangarorin biyu na tire ta yin amfani da kusoshi na kwanon rufi na M6 da goro.Haɗa tiren (tare da tabarma na roba) zuwa bayan injin muna ɗaukar skru biyu na M8 x 12.Daidaita nunin faifai biyu na baya zuwa ɓangarorin tiren.

Samfuran 1000E da 1250E: Haɗa sandunan baya biyu a bayan injin ta amfani da sukurori biyu na M8 x 16 ga kowane mashaya.Haɗa tiren (tare da tabarmar roba) zuwa bayan injin ta amfani da screws M8 x 16 guda uku.Daidaita abin wuyan tsayawa akan kowane mashaya ta baya.

7. Haɗa hannun (s) da M8 x 16 hula-head sukurori.

Model 650E da 1000E: Ya kamata a zame hannun ta ƙasa ta kusurwar da ke nuna zobe kafin haɗa hannun.

Model 1250E: Dole ne a sanya hannun da ma'aunin kusurwa a gefen hagu, kuma ƙwanƙwasa tasha ta zame a kan shi kuma a ɗaure kusa da saman hannun.

8.Model 1250E: Juya katakon lanƙwasa sama ta 180°.Cire kayan an-

gle taro mai nuna alama kuma wuce Nuni Slide akan hannun hagu.Cire sukurori biyu na hular M8 daga ma'aunin anga-block wanda aka ɗaure zuwa gindin injin ɗin kusa da hannun hagu.Haɗa Hannun Hannun Hannu zuwa katangar anka kuma ƙara maƙallan M8 cap-head sukurori da hannu sannan, ta amfani da maɓallin Allen na mm 6, ƙara ƙarar sukurori biyu sosai.

Lura:Na'urar bazai kunna ba idan waɗannan skru ba su da ƙarfi.

9.Yin amfani da chlorinated ƙarfi (ko man fetur) share share share kakin zuma-kamar shafi daga aiki saman na inji.

10.Place da gajeren matsa sanduna a cikin tire da cikakken tsawon manne mashaya a saman na'ura tare da locating bukukuwa zaune a cikin grooves a saman sur fuskar na'ura.

11.Toshe cikin tashar wuta kuma kunna babban maɓalli.Injin yana shirye yanzu

don aiki - da fatan za a koma zuwa "BasIC OPERATION1' a cikin wannan littafin.

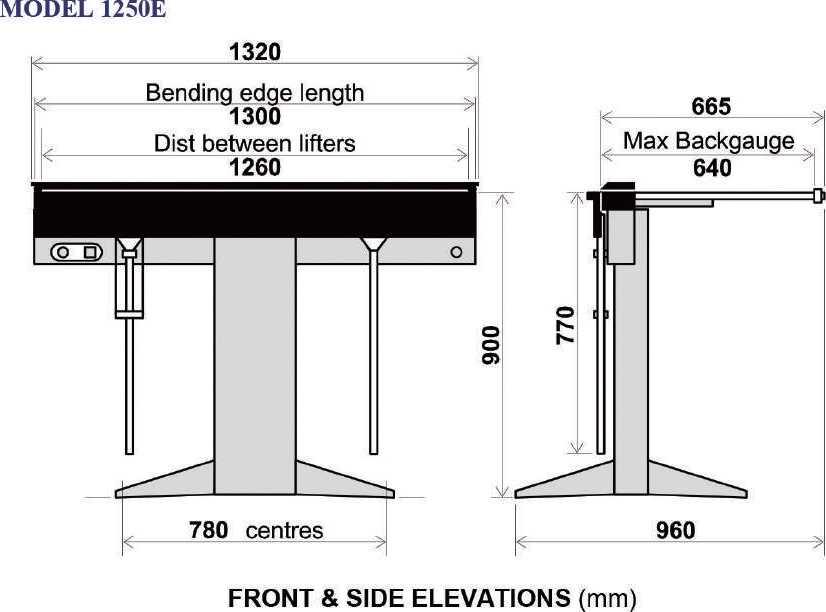

| Model 650E | 625 mm x 1.6 mm | (2ftx 16g) | 72 kg |

| Model 1000E | 1000mm x 1.6mm | (3ft x 16g) | ba kg |

| Model 1250E | 1250 mm x 1.6 mm | (4ftx 16g) | 150 kg |

KARFIN CLAMING

Jimlar ƙarfi tare da daidaitaccen mashaya mai tsayi mai tsayi:

MAGANAR NOMINAL

Nauyin Inji

| Model 650E | 4.5 ton |

| Model 1000E | 6 Tan |

| Model 1250E | 3 Tan |

LANTARKI

Mataki na 1, 220/240 V AC

Yanzu:

| Model 650E | 4 amp |

| Model 1000E | 6 amp |

| Model 1250E | 8 amp |

Zagayen aiki: 30%

Kariya: Yankewar thermal, 70°C

Sarrafa: Maɓallin farawa ... ƙarfi pre-clamping

Lanƙwasa katako microswitch...cikakkiyar matsawa

Maɓallin maɓalli...maɓallin farawa da katakon lanƙwasa dole ne a yi aiki da shi a daidai jeri mai jerawa don fara cikakken ƙarfi.

HINGES

Zane na musamman mara tsakiya don samar da na'ura mai buɗewa gabaɗaya.

Juyawa kusurwa: 180°

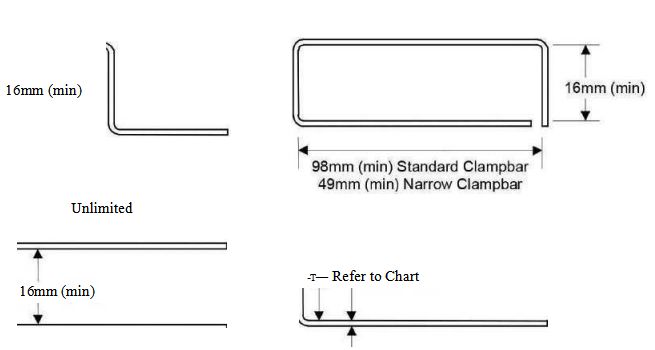

GIRMAN LAnkwasawa

KARFIN LAnkwasawa

| KYAUTATA (samarwa/mafi tsananin damuwa) | KAURI |

| M-karfe (250/320 MPa) | 1.6 mm |

| 1.2 mm | |

| 1.0 mm | |

| AluminiumGrade 5005 H34(140/160 MPa) | 1.6 mm |

| 1.2 mm | |

| 1.0 mm | |

| Bakin Karfe Darajoji 304,316 (210/600 MPa) | 1.0 mm |

| 0.9 mm ku | |

| 0.8 mm |

| FADIN LABA | KAN RADIUS |

| (mafi ƙarancin) | (na al'ada) |

| 30mm* | 3.5 mm |

| 15 mm | 2.2 mm |

| 10 mm | 1.5 mm |

| 30mm* | 1.8 mm |

| 15 mm | 1.2 mm |

| 10 mm | 1.0 mm |

| 30mm* | 3.5 mm |

| 15 mm | 3.0 mm |

| 10 mm | 1.8 mm |

(Lokacin yin amfani da madaidaicin madaidaicin manne-matsala don lanƙwasa cikakken tsawon aikin aiki)

* Tare da mashaya tsawo wanda aka dace da katako mai lanƙwasa.

GASKIYA SATIN BARKANCI

Tsawon tsayi: Model 650E: 25, 38, 52, 70, 140, 280 mm

Model 1000E & 1250E: 25, 38, 52, 70, 140, 280, 597 mm

Duk masu girma dabam (sai 597 mm) ana iya haɗa su tare don samar da gefen lanƙwasa tsakanin 25 mm na kowane tsayin da ake so har zuwa 575 mm.

SLOTTED CLampBAR

Lokacin da aka kawo shi, saiti na musamman na 8mm faɗin ramummuka yana ba da don ƙirƙirar duk girman tire a cikin kewayon da aka nuna a ƙasa:

* Don tudu masu zurfi yi amfani da Short-Camp-bar set.

| MISALI | TSAYIN TIRO | MAX.ZURFIN FARUWA |

| 650E | 15 zuwa 635 mm | 40mm* |

| 1000E | 15 zuwa 1015 min | 40mm* |

| 1250E | 15 zuwa 1265 mm | 40 inm* |

MISALIN 650E/ 1000E

GABA DA GEFE (mm)

MISALI SERIAL NO. DATE

HADIN KASAR DUNIYA

Auna juriya daga mains toshe duniya fil zuwa jikin maganadisu .... ohm

KEBE LANTARKI

Megger daga coil zuwa jikin magnet

GWAJIN ARZIKI NA MIN/MAX

A 260v: Pre-clamp....cikakken manne....saki

A 200v: Pre-clamp....saki

Pre-clamp....cikakken manne....saki

JININ INTERLOCK

Tare da kunnawa, ja HANDLE, sannan danna maɓallin START.

Duba cewa injin baya kunnawa

KUNIYA/KASHE KUNGUWA

Motsi na Lanƙwasa Beam don kunna cikakken mannewa,

auna a kasa na lankwasa katako.(4mm zuwa 6mm) mm

Juya motsi zuwa injin kashewa.Auna baya

daga 90°.(Ya kamata ya kasance cikin kewayon 15 ° + 5 °) deg

MISALIN KWALA

Karatu a gefen Mai nuna alama lokacin da aka saita katako mai lanƙwasa

zuwa 90° tare da filin injiniya.(min 89°, max 91°) deg

MAGNET JIKIN

Madaidaicin saman saman, tare da sandar gaba

(max sabawa = 0.5 mm)Imm

Lalacewar saman saman, a fadin sandunan

(max sabawa = 0.1 mm) mm

BANDING BEAM

Madaidaicin saman aiki (max sabawa = 0.25 mm)

Daidaita sandar tsawo (max sabawa = 0.25 mm)[Lura:Gwada madaidaiciya tare da madaidaiciya madaidaiciya madaidaiciya.]

BABBAN CLAMPBAR

Madaidaicin gefen lankwasawa (max ƙetare = 0.25 mm) Tsawon ɗagawa (tare da ƙwallo masu ɗagawa a cikin tsagi) (min 3 mm) Za a iya matsa ƙwallayen ɗagawa da ruwa tare da masu daidaitawa da aka saita an1nda lankwasawa katako a 90 °

shine lankwasa-bakia layi dayaku, kumaIna mmdaga, katako Tare da katako mai lanƙwasa a 90°, za a iya daidaita maƙalar gaba zuwa gaba.tabakuma a baya ta2 mm

HINGES

Bincika don lubrication akan shafts.da tubalan sassa

Bincika cewa hinges suna juyawa ta 180° kyauta kuma a hankali

Duba hingefildo bajuya.kuma an same su

An kulle ƙwaya mai riƙewa?

GWAJIN LAnkwasawa

(Matsakaicin ƙayyadaddun ƙayyadaddun lanƙwasa zuwa 90°, a ƙaramin ƙarfin wutar lantarki.)

Karfe gwajin yanki kauri

Fadin lebe

mm, Tsawon lanƙwasa

mm, lanƙwasa radius

Uniformity na kusurwar lanƙwasa (mafi girman karkata = 2°)

LABARAI

Bincika don tsabta, mannewa ga na'ura da daidaitaccen jeri.

Farantin suna & Serial No

Gargadi na lantarki

Gargadi na Clampbar

Canja lakabin

Tef ɗin aminci akan kafafun gaba

GAMA

Duba tsafta, 'yanci daga tsatsa, lahani da sauransu

SAHABBAI

Haɗuwa & Gwaji.

Binciken QA

BASIC AIKI

GARGADI

Babban fayil ɗin ƙarfe na lanƙwasawa na Jdc na iya yin jimlar ƙarfin matsi na ton da yawa (duba TAMBAYOYI).An sanye shi da kulli mai hannu biyu don taimakawa tabbatar da cewa ba za a iya kama yatsu ba da gangan a ƙarƙashin maɗaɗɗen maɗaurin lokacin da ake amfani da matsi na lantarki.

Duk da haka,yana da mahimmanci cewa ma'aikaci ɗaya ne kawai ya yi amfani da injin a lokaci ɗaya.Yana da yuwuwar haɗari ga mutum ɗaya ya saka guntun aikin kuma ya riƙe maƙallan yayin da wani ke aiki da maɓallan!

LAnkwasawa na al'ada

Tabbatar cewa wuta tana ON a tashar wutar lantarki kuma madaidaicin madaidaicin tsayi yana tsaye akan injin tare da ƙwallayen ɗagawa suna hutawa a cikin wuraren da aka gano a kowane ƙarshen.

1.Adjust for workpiece kaurita hanyar jujjuya madaidaitan madaidaicin a ko'ina a ƙarshen matsi.Ɗaga katakon lanƙwasa har zuwa matsayi 90° kuma duba cewa yana layi ɗaya zuwa gefen maƙallan maƙallan - idan ya cancanta a sake daidaita masu ɗagawa.

(Don ingantacciyar sakamako tazarar da ke tsakanin gefen ƙugiya da saman katakon lanƙwasa ya kamata a saita zuwa ɗan girma fiye da kaurin ƙarfe da za a lanƙwasa.)

2. Saka kayan aikisannan karkatar da gefen gaba na clampbar ƙasa kuma daidaita layin lanƙwasawa zuwa gefen lanƙwasawa.

3. Danna kuma ka riƙe maɓallin START.Wannan ya shafi pre-clamping.

5.The lankwasawa katako iya koma game da 10 ° zuwa 15 ° dauki matsa lamba kashe workpiece domin duba lankwasawa kwana.Juyawa da fiye da 15° yana kashe injin ta atomatik kuma ya saki aikin.

HANKALI

- Don guje wa haɗarin ɓata gefen lanƙwasawa na clampbar ko na haɗe saman saman jikin magnet,kar a sanya kananan abubuwa a ƙarƙashin manne.Mafi ƙarancin tsayin lanƙwasa shawarar da aka ba da shawarar ta amfani da madaidaicin clampbar shine mm 15, sai dai lokacin da yanki na aikin ya kasance sirara ko taushi.

- Ƙarfin ƙwanƙwasa na maganadisu ya ragu lokacin da yake zafi.Don haka don samun mafi kyawun aikiyi amfani da matsawa don kada ya wuce yadda ya kamatadon yin lanƙwasa.

WUTAR WUTA(Na'urorin haɗi na zaɓi)

BAYANIN AMFANI

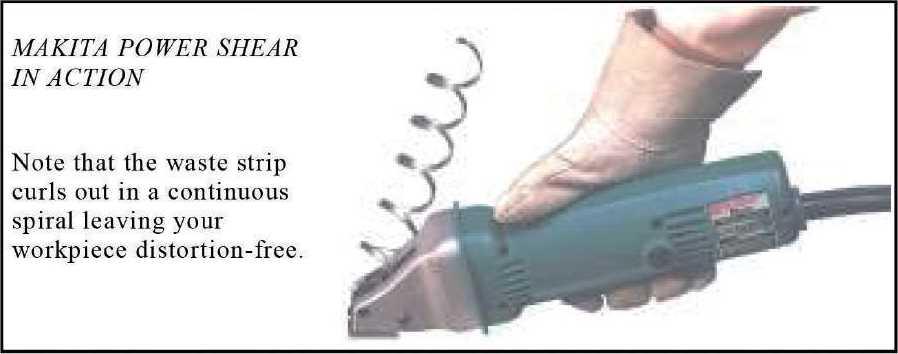

Ƙarfin wutar lantarki (dangane da Makita Model JS 1660) yana ba da hanya don yankan sheetmetal a cikin hanyar da za a bar ƙananan murdiya a cikin aikin.Wannan yana yiwuwa saboda juzu'in yana cire tarkacen shara, faɗinsa kusan mm 4, kuma galibin ɓarnar da ke tattare da ƙwanƙwasa ke shiga cikin wannan tsibiri.Don amfani tare da Jdcbend an sa shear ɗin tare da jagorar maganadisu na musamman.

Shear yana aiki da kyau a hade tare da Jdcbend Sheetmetal Folder;da Jdcbend yana samar da duka hanyar riƙe da workpiece gyarawa yayin da ake yanke da kuma a wajen shiryar da kayan aiki sabõda haka, sosai madaidaiciya yanke zai yiwu.Yanke kowane tsayi za a iya sarrafa shi cikin ƙarfe har zuwa kauri 1.6 mm ko aluminum har zuwa 2 mm kauri.

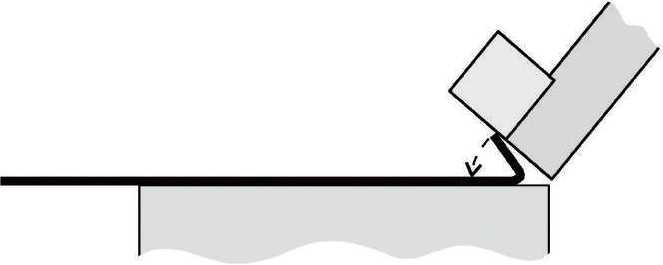

Don amfani da kayan aiki da farko sanya sheetmetal workpiece a karkashin clampbar na Jdcbend da kuma sanya shi domin yankan line daidai ne.] mma gaban gefen Lankwasawa Beam.

Za a sami maɓalli mai alamar "NORMAL / AUX CLAMP,, kusa da babban maɓallin ON/KASHE. Canja wannan zuwa matsayin AUX CLAMP don riƙe kayan aikin da kyau a matsayi.

Sanya juzu'i a ƙarshen hannun dama na Jdcbend kuma tabbatar da cewa abin da aka makala na jagorar maganadisu ya shiga gefen gaba na Lanƙwasawa Beam.Fara jujjuyawar wutar lantarki sannan kuma tura shi daidai gwargwado har sai an gama yanke.

Bayanan kula:

- Don ingantaccen aiki yakamata a gyara tsaftar ruwa don dacewa da kaurin kayan da za'a yanke.Da fatan za a karanta umarnin Makita da aka kawo tare da juzu'i na JS1660.

- Idan Shear bai yanke kyauta ba duba cewa ruwan wukake masu kaifi ne.

RUWAN LABA

NINKA LEBE (HEM)

Dabarar da ake amfani da ita don nadawa lebe ya dogara da kauri na workpiece kuma zuwa wani matsayi, akan tsayinsa da faɗinsa.

Bakin Aiki (har zuwa 0.8 mm)

1. Ci gaba kamar yadda ake lankwasawa na yau da kullun amma ci gaba da lanƙwasawa gwargwadon yiwuwa (135°).

2.Cire clampbar kuma bar workpiece a kan na'ura amma matsar da shi a baya game da 10 mm.Yanzu juya katakon lanƙwasa don danne leɓe.(Ba a buƙatar dannawa).[Lura: Kada kuyi ƙoƙarin samar da kunkuntar lebe akan kayan aiki masu kauri].

3.With bakin ciki workpieces, da/ko inda lebe ne ba ma kunkuntar, a more m flattening za a iya samu ta bin tare da Magnetic clamping kawai:

GANGAR JIKI

SAMUN KISHIYA

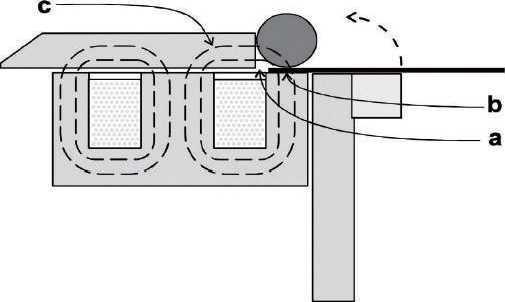

Mirgina gefuna ana kafa ta nannade da workpiece a kusa da wani zagaye karfe mashaya ko yanki na lokacin farin ciki-bango bututu.

1.Position da workpiece, clampbar da mirgina mashaya kamar yadda aka nuna.

a) Tabbatar cewa clampbar baya zoba sandar gaba na ma chine a "a" saboda wannan zai ba da damar jujjuyawar maganadisu ta ƙetare sandar birgima kuma don haka matsawa zai yi rauni sosai.

b) Tabbatar cewa sandar birgima tana hutawa akan sandar gaban ƙarfe na ma chine ("b") kuma kada ta sake komawa kan ɓangaren aluminum na saman.

c) Manufar clanipbar ita ce samar da hanyar maganadisu ("c") zuwa sandar birgima.

2.Wrap da workpiece kamar yadda zai yiwu sa'an nan sake mayar da matsayi kamar yadda aka nuna.

3. Maimaita mataki na 2 kamar yadda ake bukata.

GWADA BAYANIN

UMARNI DON SAMUN KASHIN GWAJI

Domin samun masaniya da injin ku da nau'in ayyukan da za a iya yi da shi, ana ba da shawarar cewa a samar da wani yanki na gwaji kamar yadda aka bayyana a ƙasa:

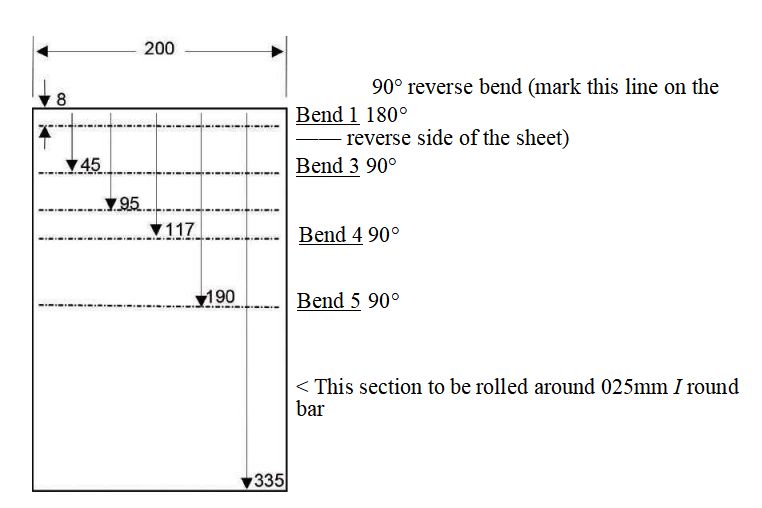

1.Zaɓi wani yanki na 0.8 mm m m karfe ko aluminum sheet da yanke shi zuwa 335 x 200 mm.

2. Alama layi akan takardar kamar yadda aka nuna a ƙasa:

3. DaidaitoLankwasa 1da kuma samar da lebe a gefen aikin aikin.(Duba

3. DaidaitoLankwasa 1da kuma samar da lebe a gefen aikin aikin.(Duba "LABA NINYE")

4. Juya yanki na gwajin kuma zame shi a ƙarƙashin matsi, barin gefen da aka naɗe zuwa gare ku.Mayar da maɗaurin gaba da layiLankwasa 2.Yi wannan lanƙwasa zuwa 90°.Ya kamata yanki gwajin ya yi kama da haka:

…GWADA BAYANIN

5. Juya gwajin yanki da yinLankwasa 3, lankwasa 4kumaLankwasa 5kowane zuwa 90 °

6.Don kammala siffar, sauran yanki za a yi birgima a kusa da 25 mm diamita na shinge na karfe.

- Zaɓi maƙallan mm 280 kuma sanya shi, yanki na gwaji da sandar zagaye akan injin kamar yadda aka nuna a ƙarƙashin "ROLLED EDGE" a baya a cikin wannan jagorar.

- Riƙe sandar zagaye a matsayi da hannun dama kuma yi amfani da pre clamping ta latsa da riƙe maɓallin START da hannun hagu.Yanzu yi amfani da hannun dama don cire hannun kamar yin lanƙwasa na yau da kullun (ana iya saki maɓallin START).Kunsa kayan aikin kamar yadda zai yiwu (kimanin 90 °).Sake sanya kayan aikin (kamar yadda aka nuna a ƙarƙashin "Forming a Rolled Edge") kuma kunsa sake.Ci gaba har sai an rufe nadi.

Siffar gwajin yanzu ta cika.

Akwatuna...

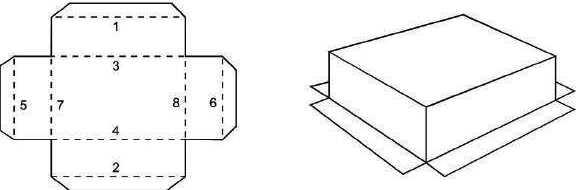

YIN KWALAKAN (Amfani da GAJANIN TSORO)

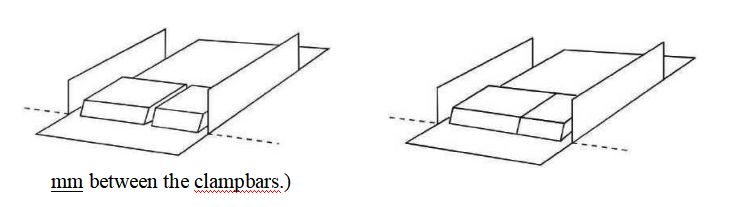

Akwai hanyoyi da yawa na shimfida akwatuna da hanyoyi masu yawa na nade su sama.JDCBEND ya dace da samar da kwalaye, musamman ma hadaddun, saboda iyawar yin amfani da gajerun sanduna don samar da folds ba tare da tangarɗa ba ta folds na baya.

Kwalayen Filaye

1.Yi lankwasa biyun farko ta amfani da dogon matsi kamar na lankwasawa na yau da kullun.

2.Zaɓi ɗaya ko fiye na guntun ƙugiya da matsayi kamar yadda aka nuna.(Ba lallai ba ne a gyara daidai tsawon lokacin da lanƙwasawa zai ɗauki rata na akalla20 mmtsakanin clampbars.)

Don lanƙwasa har zuwa tsayin mm 70, kawai zaɓi mafi girman yanki wanda zai dace.Don tsayi mai tsayi yana iya zama dole a yi amfani da guntu manne da yawa.Kawai zaɓi mafi tsawo clampbar wanda zai dace a ciki, sannan mafi tsayi wanda zai dace da ragowar tazarar, da yuwuwar na uku, don haka yin tsayin da ake buƙata.

Don maimaita lankwasawa za'a iya haɗa guntuwar matsi tare don yin raka'a ɗaya tare da tsayin da ake buƙata.A madadin, idan akwatunan suna da ɓangarorin da ba su da zurfi kuma kuna da samuwa adunƙule clampbar,sa'an nan yana iya zama mafi sauri don yin akwatunan daidai da trays marasa zurfi.(Duba sashe na gaba: TRAYS)

Akwatunan lefe

Ana iya yin akwatunan lefe ta amfani da daidaitaccen saitin gajerun matsi idan har ɗayan girman ya fi faɗin matse (98 mm).

1.Amfani da cikakken tsawon clampbar, samar da tsawon hikima folds 1, 2, 3, &4.

2.Zaɓi gajeriyar matse (ko wataƙila biyu ko uku an haɗa tare) tare da tsawon aƙalla faɗin leɓe ya fi faɗin akwatin (domin a cire shi daga baya).Form folds 5, 6, 7 & 8. Yayin da kake ƙirƙirar folds 6 & 7, yi hankali don jagorantar kusurwa

... KASUWANCI...

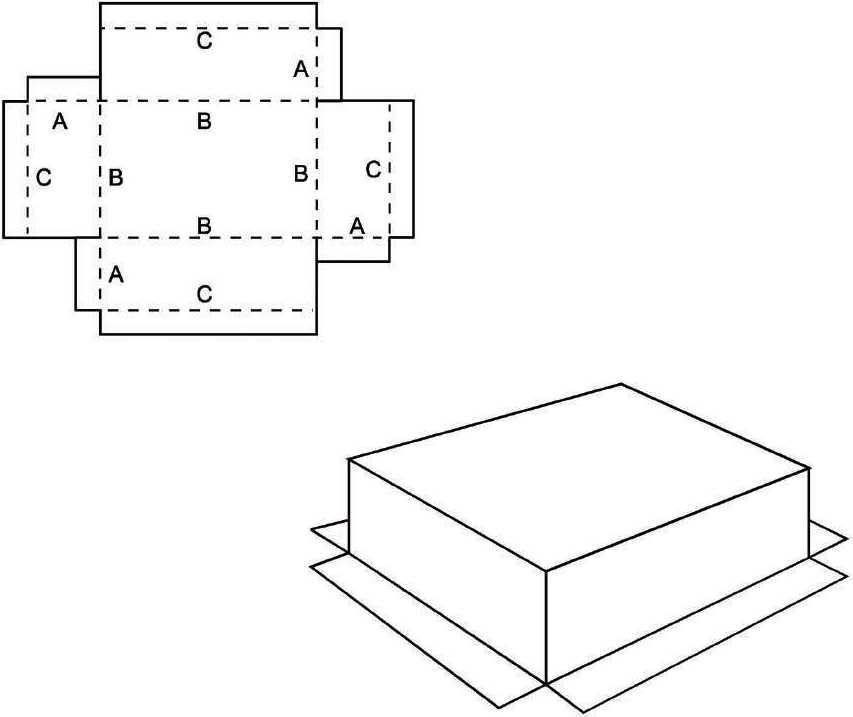

Kwalaye tare da iyakar iyakar

Akwatin da aka yi da ƙofofin daban yana da fa'idodi da yawa:

-yana adana kayan idan akwatin yana da bangarorin zurfi,

-Ba ya buƙatar noma kusurwa,

- duk yanke-fita za a iya yi tare da guillotine;

- duk nadawa za a iya yi tare da bayyananne cikakken tsawon clampbar;

da wasu nakasu:

- Dole ne a samar da ƙarin folds.

- dole ne a haɗa ƙarin sasanninta, kuma

- ƙarin gefuna na ƙarfe da masu ɗaure suna nunawa akan akwatin da aka gama.

Yin irin wannan akwatin yana tsaye gaba kuma ana iya amfani da matsi mai tsayi don duk folds.

1.Shirya ɓangarorin kamar yadda aka nuna a ƙasa.

2.Na farko samar da hudu folds a cikin babban workpiece.

4.Haɗa akwatin tare.

Akwatunan flanged tare da sasanninta na fili

Akwatunan kusurwa masu kusurwa tare da flanges na waje suna da sauƙin yin idan tsayi da faɗin sun fi faɗin clampbar na 98 mm.Ƙirƙirar kwalaye tare da flanges na waje yana da alaƙa da yin SAUKI TOP-HAT (wanda aka kwatanta a wani sashe na gaba - duba Abubuwan da ke ciki).

4.Shirya komai.

5.Yin amfani da matsi mai cikakken tsayi, samar da folds 1, 2, 3 & 4.

6. Saka flange a ƙarƙashin clampbar don samar da ninka 5, sannan ninka 6.

7.Amfani da dacewa gajeriyar clampbars, cikakken folds 7 & 8.

... Kwalaye

Akwatin Flanged tare da Shafukan kusurwa

Lokacin yin akwati mai flanged na waje tare da shafuka na kusurwa kuma ba tare da amfani da keɓantaccen yanki na ƙarshen ba, yana da mahimmanci a samar da folds a cikin daidaitaccen jeri.

1.Shirya blank tare da shafukan kusurwa da aka shirya kamar yadda aka nuna.

3.A daidai wannan ƙarshen clampbar mai tsayi mai tsayi, samar da foldsnBn zuwa 45° kawai.Yi haka ta hanyar saka gefen akwatin, maimakon kasan akwatin, a ƙarƙashin manne.

4.A sauran karshen cikakken tsawon clampbar, samar da flange folds "C" zuwa 90 °.

5.Amfani da dacewa gajeriyar clampbars, cikakken foldsnBnzuwa 90.

6. Shiga sasanninta.

Ka tuna cewa don akwatuna masu zurfi yana iya zama mafi kyau don yin akwatin tare da sassa na ƙarshen.

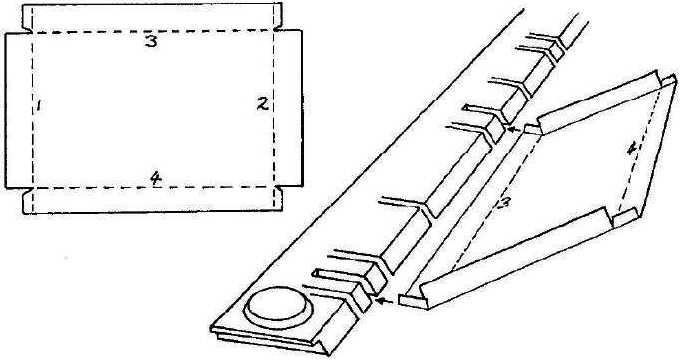

SLOTTED CLampBAR

YIN FARUWA (Amfani da SLOTTED CLampBAR)

The Slotted Clampbar, lokacin da aka kawo shi, yana da kyau don yin tire mai zurfi da kwanon rufi cikin sauri da daidai.Fa'idodin matsi mai ramin ramuka akan saitin gajerun ƙugiya don yin tire shine cewa gefen lanƙwasawa yana daidaitawa ta atomatik zuwa sauran na'ura, kuma clampbar yana ɗaga kai tsaye don sauƙaƙe shigarwa ko cire kayan aikin.Ba-da-ƙasa, za a iya amfani da gajerun ƙulle-ƙulle don samar da trays na zurfi marar iyaka, kuma ba shakka, sun fi kyau don yin siffofi masu rikitarwa.

Ana amfani da su, ramukan suna daidai da ramukan da aka bari tsakanin yatsu na akwatin taron taron & injin nadawa.Nisa na ramummuka shine wanda kowane ramummuka guda biyu zasu dace da tire akan girman girman mm 10, kuma lamba da wuraren ramin sun kasance kamar haka.ga duk girman tire, koyaushe ana iya samun ramummuka guda biyu waɗanda zasu dace da shi.(Mafi gajarta kuma mafi tsayin girman tire mai ramin ramin clampbar zai ɗauka an jera su a ƙarƙashin SPECIFICATIONS.)

Don ninka tire mai zurfi:

- Ninka farkon bangarorin biyu gaba da juna da shafukan kusurwa ta amfani da matsi mai ramin ramuka amma yin watsi da kasancewar ramukan.Waɗannan ramummuka ba za su sami wani tasiri mai fa'ida akan folds ɗin da aka gama ba.

- Yanzu zaɓi ramummuka biyu tsakanin waɗanda za a ninka saura bangarorin biyu.Wannan hakika yana da sauqi kuma abin mamaki cikin sauri.Kawai jera gefen hagu na tiren ɓangarorin da aka yi tare da ramin hagu kuma duba idan akwai ramin gefen dama don turawa cikin;in ba haka ba, zame tiren tare har sai gefen hagu ya kasance a ramin na gaba kuma a sake gwadawa.Yawanci, yana ɗaukar kusan 4 irin waɗannan ƙoƙarin don nemo ramummuka biyu masu dacewa.

- A ƙarshe, tare da gefen tire a ƙarƙashin madaidaicin kuma tsakanin ramukan da aka zaɓa, ninka sauran bangarorin.Bangarorin da aka kafa a baya suna shiga cikin zaɓaɓɓun ramummuka yayin da aka kammala folds na ƙarshe.

Tare da tsayin tire waɗanda ke kusan muddin maɗaurin yana iya zama dole a yi amfani da ƙarshen matse ɗaya a madadin ramin.

BAYANI

AMFANI DA TSAFIYA

Ƙididdiga na baya suna da amfani lokacin da dole ne a yi babban adadin lanƙwasa duk wanda ke da nisa ɗaya daga gefen aikin aikin.Da zarar an saita taswirar baya daidai kowane adadin lanƙwasa za a iya yin ba tare da buƙatar kowane aunawa ko alama akan kayan aikin ba.

A al'ada za a yi amfani da tashoshi na baya tare da sandar da aka ɗora musu don samar da wani dogon saman da za a yi la'akari da gefen aikin.Ba a bayar da takamaiman mashaya ba amma za a iya amfani da yanki mai tsawo daga katakon lanƙwasa idan babu wata sandar da ta dace.

NOTE:Idan ana buƙatar saita tashakarkashinclampbar, to, ana iya yin wannan ta amfani da tsiri na sheetmetal irin kauri kamar na workpiece, a tare da backstops.

GASKIYA

DUBI SAMUN INGANTACCEN NA'ARKI

Dukkanin saman aikin Jdcbend an ƙera su don zama madaidaiciya da lebur zuwa tsakanin 0.2 mm a tsawon tsayin injin.

Abubuwan da suka fi mahimmanci sune:

- madaidaiciyar farfajiyar aiki na katako mai lanƙwasawa,

- madaidaiciyar gefen lanƙwasawa na sandar matsa, da

- daidaitawar wadannan saman biyu.

Ana iya duba waɗannan saman tare da madaidaiciyar madaidaiciya amma wata hanya mai kyau ta dubawa ita ce a yi la'akari da saman juna.Don yin wannan:

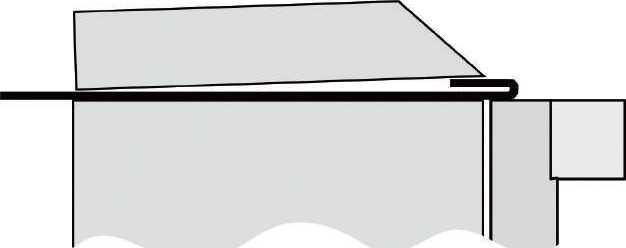

- Juya katakon lanƙwasa har zuwa matsayi 90° kuma riƙe shi a can.(Za a iya kulle katako a wannan matsayi ta hanyar sanya ƙwanƙwan ƙwanƙolin tsayawa a baya bayan zamewar kusurwa a kan rike).

- Kula da tazarar da ke tsakanin gefen lanƙwasawa na sandar matse da aikin aikin katakon lanƙwasawa.Yin amfani da masu daidaita sandar matse suna saita wannan tazar zuwa mm 1 a kowane ƙarshen (amfani da guntun guntun takarda, ko ma'aunin ji).

Bincika cewa tazarar iri ɗaya ce ta gaba ɗaya tare da maƙalar.Duk wani bambancin ya kamata ya kasance a cikin ± 0.2 mm.Tliat shine ratar kada ta wuce 1.2 mm kuma kada ta kasance ƙasa da 0.8 mm.(Idan masu daidaitawa ba su karanta iri ɗaya ba a kowane ƙarshen sai a sake saita su kamar yadda aka rubuta ƙarƙashin MAINTENANCE).

Bayanan kula:

- Madaidaicin abin matse kamar yadda aka gani a tsayi (daga gaba) ba shi da mahimmanci saboda wannan yana lalacewa ta hanyar matsawar maganadisu da zaran an kunna injin.

- Tazarar da ke tsakanin katakon lanƙwasa da jikin maganadisu (kamar yadda aka gani a cikin tsari-duba tare da katako mai lanƙwasa a matsayinsa na gida) yawanci kusan 2 zuwa 3 mm.Wannan gibin shinebawani bangare na aikin injin kuma baya shafar daidaiton lanƙwasawa.

- Jdcbend na iya samar da ninki mai kaifi a cikin siraran ma'auni kuma a cikin kayan da ba na ƙarfe ba kamar aluminum da jan karfe.Koyaya a cikin ma'auni masu kauri na ƙarfe da bakin karfe kar ku yi tsammanin cimma ninki mai kaifi (duba ƙayyadaddun bayanai).

- Za'a iya haɓaka daidaituwar lanƙwasa a cikin ma'auni masu kauri ta hanyar amfani da guntun guntun kayan aikin don cika abubuwan da ba a yi amfani da su ba a ƙarƙashin matsi.

KIYAWA

SURFASIN AIKI

Idan saman injin ɗin ya zama yayi tsatsa, ɓata ko tsufa, ana iya gyara su cikin sauri.Duk wani burbushin da aka taso ya kamata a shigar da shi a hankali, kuma a shafa saman da takarda Emery P200.A ƙarshe yi amfani da feshi-kan rigakafin tsatsa kamar CRC 5.56 ko RP7.

LABARIN HANYA

Idan babban fayil ɗin sheetmetal na Jdcbend yana cikin amfani akai-akai, to sai a yi man shafawa ko mai da hinges sau ɗaya a wata.Idan ba a yi amfani da na'ura kaɗan ba, to za'a iya sanya mashin ɗin mai sau da yawa.

Ana ba da ramukan mai mai a cikin labule biyu na babban farantin hinge, kuma madaidaicin saman ɓangaren ɓangaren ya kamata a shafa masa mai.

Masu daidaitawa

Masu daidaitawa a ƙarshen babban clampbar shine sarrafa izinin kauri na kayan aiki tsakanin gefan lanƙwasa da katako mai lanƙwasawa.An saita masu gyara masana'anta don ba da izinin kauri na 1 mm lokacin da masu daidaitawa "1" don sake saita wannan, ci gaba kamar haka:

1. Rike katakon lankwasawa a 90.

3. Yin watsi da alamomi masu nunawa, daidaita masu daidaitawa har sai sassan 1 mm kawai suna da sauƙi "nipped" tsakanin lanƙwasa-baki da katako mai lankwasa.

4.Yin amfani da maɓallin Allen na 3 mm, a hankali sassauta ƙugiya don 'yantar da zoben da aka ƙulla na ɗaya daga cikin masu daidaitawa.Sannan juya zoben har sai alamar tsaga ta nuna "1n.Yi wannan ba tare da jujjuya jikin tallan na ciki ba.Sa'an nan kuma sake matse grub-screw.

5. Sake saita sauran masu daidaitawa a daidai wannan hanya.

Ƙwallon ɗagawa da aka ɗora a cikin bazara a ƙarƙashin masu daidaitawa na iya mannewa idan ƙazanta ko damshin da ke haifar da tsatsa ya shiga. Idan hakan ya faru, gyara ta ta hanyar danna ƙwallon ciki da waje tare da kayan aiki mara ƙarfi yayin fesa cikin mai mai shiga kamar CRC 5.56 ko RP7.

MATSALAR HARBI…

Hanya mafi sauƙi don gyara matsalolin wutar lantarki ita ce yin odar sauya tsarin lantarki daga masana'anta.Ana ba da wannan akan tsarin musayar don haka yana da tsada sosai.Kafin aikawa da tsarin musanya kuna iya son duba waɗannan abubuwan:

1.Machine baya aiki kwata-kwata:

a) Bincika cewa akwai wutar lantarki a na'ura ta hanyar lura da hasken matukin jirgi a cikin ON/KASHE.

b) Idan akwai wuta amma har yanzu injin ya mutu amma yana jin zafi sosai to yankewar zafin na iya yin rauni.A wannan yanayin jira har sai injin ya huce (kimanin % awa daya) sannan a sake gwadawa.

c) Makullin farawa mai hannu biyu yana buƙatar danna maɓallin STARTkafinan ja hannun.Idan aka ja hannunna farkoto injin ba zai yi aiki ba.Hakanan yana iya faruwa cewa katako mai lanƙwasa yana motsawa (ko kuma ya fashe) isasshe don sarrafa aikinnAngle microswitch" kafin a danna maɓallin START. Idan wannan ya faru a tabbata an fara tura hannun gaba ɗaya. Idan wannan matsala ce mai tsayi to yana nuna cewa mai kunnawa microswitch yana buƙatar daidaitawa (duba ƙasa).

d) Wata yuwuwar ita ce maɓallin START na iya zama kuskure.Idan kana da Model 1250E ko mafi girma to duba idan za'a iya fara na'urar da ɗaya daga cikin madadin maɓallan START ko maɓallan ƙafa.

e) Hakanan duba mai haɗawa wanda ke haɗa tsarin lantarki tare da na'urar maganadisu.

f) Idan clamping bai yi aiki ba amma clampbar ya ƙaresakina START button to wannan yana nuna cewa 15 microfarad (10 gF akan 650E) capacitor ba daidai ba ne kuma yana buƙatar sauyawa.

g) Idan na'urar ta busa fis na waje ko kuma ta zagaya da na'urorin da'ira lokacin da ake aiki da ita to abin da ya fi dacewa shine busa gada-gyara.

2.Lieht clamping oiwrates amma cikakken clamping doe§ ba:

a) Duba cewa "Angle Microswtich" ana kunna shi daidai.[Wannan maɓalli ana sarrafa shi ta wani yanki mai murabba'in tagulla wanda ke haɗe zuwa kusurwar da ke nuna na'ura.Lokacin da aka ja riƙon katakon lanƙwasa yana juyawa wanda ke ba da juyi ga mai kunna tagulla.Ac tuator bi da bi yana aiki da microswitch a cikin taron lantarki. Cire hannun waje sannan ku shiga. Ya kamata ku iya jin microswitch yana danna ON da KASHE (idan babu hayaniyar baya da yawa).

Idan mai kunnawa bai danna ON da KASHE ba sai a lankwasa katakon lankwasa daidai sama domin a iya ganin mai kunna tagulla.Juyawa katakon lanƙwasawa sama da ƙasa.Mai kunnawa ya kamata ya juya don mayar da martani ga katako mai lanƙwasa (har sai ya kama a tsayawarsa).Idan bai yi ba to yana iya buƙatar ƙarin ƙarfi kama.A kan rashin ƙarfi na 1250E yawanci yana da alaƙa da sukurori guda biyu na M8 cap-head a kowane ƙarshen mai kunnawa.

MATSALAR HARBI

shaft ba m.Idan mai kunnawa ya juya

kuma clutches OK amma har yanzu baya danna microswitch to yana iya buƙatar daidaitawa.Don yin wannan da farko cire na'urar daga tashar wutar lantarki sannan cire panel access panel.

A kan Model 1250E za a iya daidaita wurin kunnawa ta hanyar jujjuya abin da ke wucewa ta cikin mai kunnawa.Ya kamata a gyara dunƙule kamar yadda maɓallin ke dannawa lokacin da gefen ƙasa na katako mai lanƙwasa ya motsa kusan 4 mm.(A kan 650E da 1000E ana samun daidaitattun daidaitattun ta hanyar lanƙwasa hannun microswitch.)

b) Idan microswitch bai danna ON da KASHE ba ko da yake mai kunnawa yana aiki da kyau to ana iya haɗa shi da kansa a ciki kuma yana buƙatar maye gurbinsa.

c) Idan na'urarka tana sanye da na'ura mai ba da hanya tsakanin hanyoyin sadarwa to ka tabbata an canza ta zuwa matsayin "NORMAL".(Ƙaƙwalwar haske kawai za a iya amfani da shi idan mai sauyawa yana cikinnAUX CLAMP" matsayi.)

3 Clamping Yayi kyau amma Clampbars ba sa saki lokacin da injin ya kashe:

Wannan yana nuna gazawar da'irar demagnetising na baya.Mafi mahimmancin abin da zai haifar da shi shine hura wutar lantarki 6.8 Q.Hakanan duba duk diodes da kuma yiwuwar manne lambobi a cikin relay.

4 Injin ba zai yi nauyi ba takardar:

a) Duba cewa aikin yana cikin ƙayyadaddun na'ura.Musamman lura cewa ga 1.6 mm (16 ma'auni) lankwasawa datsawo mashayadole ne a dace da katako mai lanƙwasa kuma mafi ƙarancin faɗin leɓe shinemm 30.Wannan yana nufin cewa aƙalla milimita 30 na abu dole ne ya fito daga gefen lanƙwasawa na clampbar.(Wannan ya shafi duka aluminum da karfe.)

Lokacin aikawa: Oktoba-11-2022