MAGNABEND - MUHIMMANCIN TSIRA

Basic Magnet Design

An ƙera na'urar Magnabend azaman magnetin DC mai ƙarfi tare da iyakataccen zagayowar aiki.

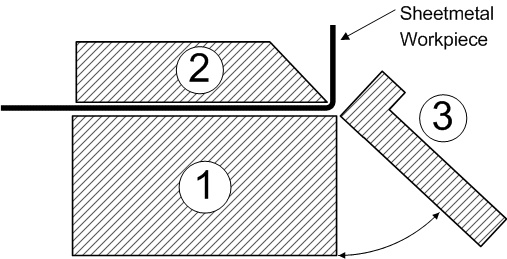

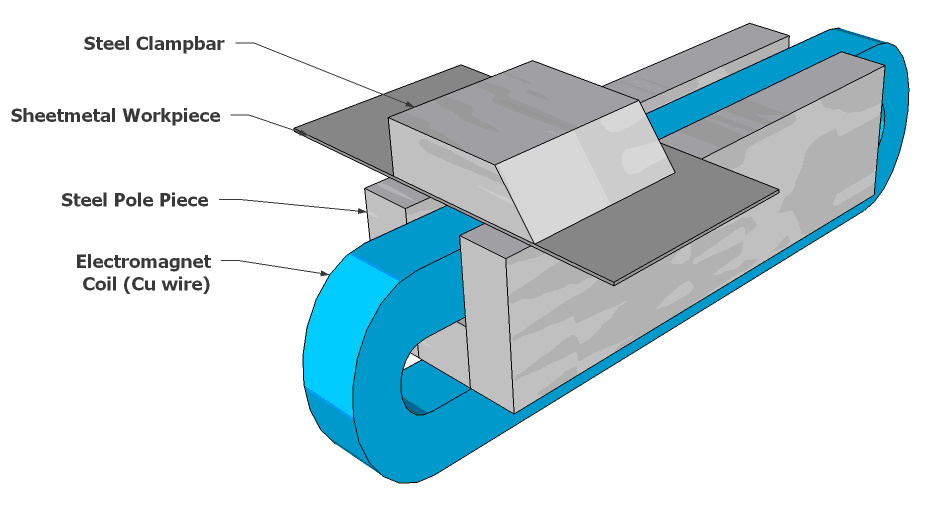

Injin ya ƙunshi sassa 3 na asali:-

Jikin maganadisu wanda ke samar da gindin injin kuma yana ƙunshe da coil-magnet.

Matsakaicin manne wanda ke ba da hanya don jujjuyawar maganadisu tsakanin sandunan sandunan maganadisu, kuma ta haka ne ke manne kayan aikin sheetmetal.

Lanƙwasawa katako wanda aka pivoted zuwa gaban gaban magnet jiki da kuma samar da wata hanya don amfani da lankwasawa da workpiece.

Tsarin Magnet-Jiki

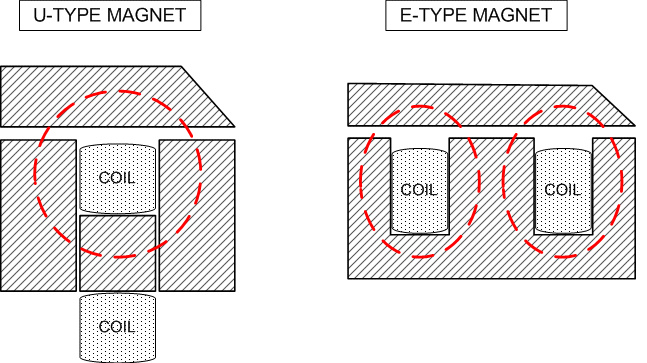

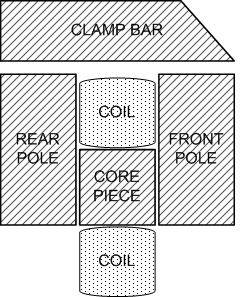

Saituna daban-daban suna yiwuwa ga jikin magnet.

Anan akwai 2 waɗanda aka yi amfani da su don injin Magnabend:

Layukan jajayen da aka tsinke a cikin zanen da ke sama suna wakiltar hanyoyin jujjuyawar maganadisu.Lura cewa ƙirar "U-Type" tana da hanyar juzu'i guda ɗaya (1 biyu na sanduna) yayin da ƙirar "E-Type" tana da hanyoyin juzu'i 2 (biyu na sanduna biyu).

Kwatancen Kanfigareshan Magnet:

Tsarin nau'in E-type ya fi dacewa fiye da tsarin U-type.

Don fahimtar dalilin da yasa wannan yake haka la'akari da zane biyu da ke ƙasa.

A gefen hagu akwai ɓangaren giciye na maganadisu nau'in U kuma a dama akwai magneto mai nau'in E wanda aka yi ta hanyar haɗa nau'ikan U-2 iri ɗaya.Idan kowane saitin maganadisu yana motsa shi ta hanyar coil mai juyi ampere iri ɗaya to a sarari maganan magana mai ninka biyu (nau'in E) zai sami ƙarfin matsawa sau biyu.Hakanan yana amfani da ƙarfe sau biyu fiye da haka amma da wuya sauran waya don nada!(Zaton dogon zane na coil).

(Ƙananan adadin ƙarin waya za a buƙaci kawai saboda ƙafafu 2 biyu na coil sun fi gaba a cikin ƙirar "E", amma wannan ƙarin ya zama maras muhimmanci a cikin dogon ƙirar coil kamar yadda ake amfani da shi don Magnabend).

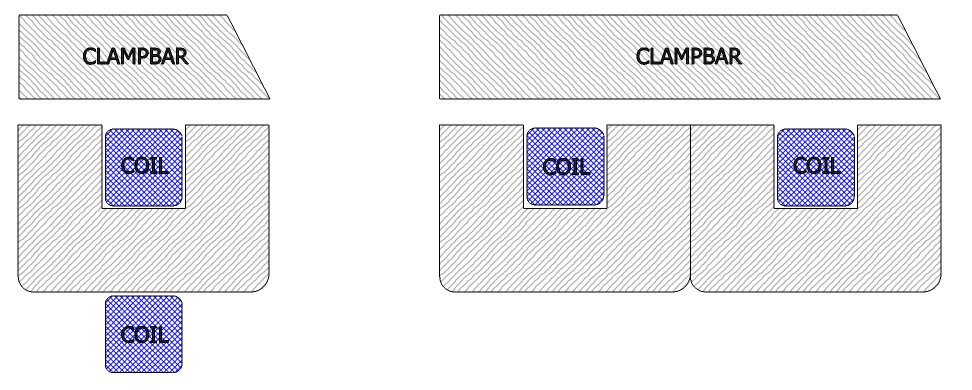

Super Magnabend:

Don gina maganadisu mafi ƙarfi har ma za a iya tsawaita ra'ayin "E" kamar wannan ƙa'idar-E sau biyu:

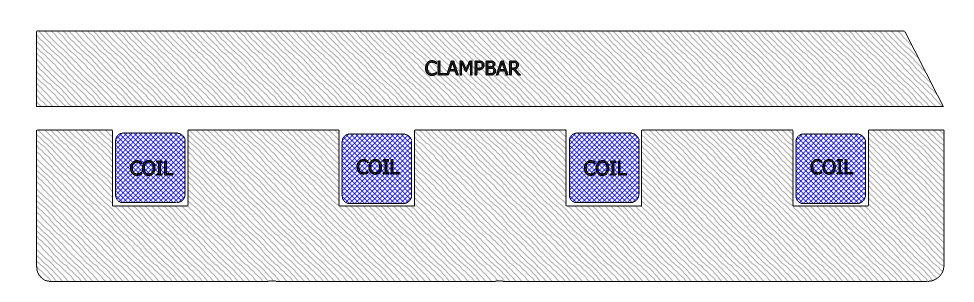

Samfurin 3-D:

A ƙasa akwai zane na 3-D yana nuna ainihin tsarin sassa a cikin nau'in maganadisu na U:

A cikin wannan ƙira, sandunan gaba da na baya sun rabu daban kuma an haɗa su da kusoshi zuwa ɓangaren Core.

Ko da yake bisa ka'ida, zai yiwu a na'ura nau'in magnetin nau'in U-nau'i daga karfe guda ɗaya, to ba zai yiwu a shigar da coil ɗin ba don haka za a sami rauni a wurin (akan injin magnet ɗin da aka yi masa). ).

A cikin yanayin samarwa yana da matuƙar kyawawa don samun damar iskar coils daban (a kan tsohon na musamman).Don haka ƙirar nau'in U-nau'in ƙirar ƙirar ƙirar ƙirar ƙirar ƙira ce ta yadda ya kamata.

A gefe guda kuma ƙirar E-type tana ba da kanta da kyau ga jikin maganadisu da aka kera daga karfe guda ɗaya saboda ana iya shigar da coil ɗin da aka riga aka yi cikin sauƙi bayan an naɗa jikin magnet ɗin.Jikin maganadisu guda ɗaya shima yana yin mafi kyawun maganadisu saboda bashi da wani gibin gini wanda in ba haka ba zai rage ƙarfin maganadisu (kuma saboda haka maƙarƙashiyar ƙarfi) kaɗan.

(Mafi yawan Magnabends da aka yi bayan 1990 sun yi amfani da ƙirar E-type).

Zaɓin Kayan Aikin Gina Magnet

Dole ne a yi jikin maganadisu da ƙugiya daga kayan ferromagnetic (magnetisable).Karfe shine mafi arha kayan ferromagnetic kuma shine zaɓi na zahiri.Koyaya, akwai nau'ikan ƙarfe na musamman waɗanda za'a iya la'akari dasu.

1) Silicon Karfe : High resistivity karfe wanda yawanci samuwa a cikin bakin ciki laminations da ake amfani da AC transformers, AC maganadiso, relays da dai sauransu Its kaddarorin ba a bukatar Magnabend wanda shi ne a DC maganadiso.

2) Ƙarfe mai laushi: Wannan abu zai nuna ƙananan ragowar magnetism wanda zai yi kyau ga na'ura na Magnabend amma yana da laushi a jiki wanda ke nufin cewa zai zama mai sauƙi kuma ya lalace;yana da kyau a warware ragowar matsalar maganadisu ta wata hanya dabam.

3) Cast Iron: Ba a sauƙaƙe magnetized kamar karfen birgima amma ana iya la'akari da shi.

4) Bakin Karfe Nau'in 416 : Ba za a iya yin maganadisu da ƙarfi kamar ƙarfe ba kuma ya fi tsada sosai (amma yana iya zama da amfani ga ƙasan bakin ciki mai karewa a jikin magnet).

5) Bakin Karfe Nau'in 316 : Wannan nau'in ƙarfe ba na ƙarfe ba ne kuma don haka bai dace da komai ba (sai dai kamar yadda yake a cikin 4 a sama).

6) Matsakaicin Karfe Karfe, nau'in K1045: Wannan kayan yana da kyau sosai don ginin maganadisu, (da sauran sassan injin).Yana da wuyar gaske a yanayin da aka kawota kuma yana aiki da kyau.

7) Medium Carbon Karfe Nau'in CS1020: Wannan karfe ba shi da wahala kamar K1045 amma yana da sauƙin samuwa kuma don haka yana iya zama mafi kyawun zaɓi don gina injin Magnabend.

Lura cewa mahimman kaddarorin da ake buƙata sune:

Babban jikewa magnetization.(Yawancin gami da ƙarfe sun cika a kusa da 2 Tesla),

Samar da girman sashe masu amfani,

Juriya ga lalacewa na bazata,

Machinability, da

Madaidaicin farashi.

Matsakaicin karfen carbon ya dace da duk waɗannan buƙatun da kyau.Hakanan za'a iya amfani da ƙananan ƙarfe na carbon amma ba shi da juriya ga lalacewa na faruwa.Har ila yau, akwai wasu na'urori na musamman, irin su supermendur, waɗanda ke da mafi girman saturation magnetisation amma ba za a yi la'akari da su ba saboda tsadar su sosai idan aka kwatanta da karfe.

Matsakaicin karfen carbon yana nuna wasu ragowar maganadisu wanda ya isa ya zama abin damuwa.(Duba sashe akan Residual Magnetism).

The Coil

Nada shine abin da ke motsa motsin maganadisu ta hanyar lantarki.Ƙarfinsa na maganadisu shine kawai samfurin adadin juyi (N) da na'ura mai juyi (I).Don haka:

N = adadin juyawa

I = halin yanzu a cikin iska.

Bayyanar "N" a cikin dabarar da ke sama yana haifar da kuskuren gama gari.

Ana kyautata zaton cewa kara yawan juyi zai kara karfin maganadisu amma gaba daya hakan baya faruwa saboda karin juyi shima yana rage na yanzu, I.

Yi la'akari da coil ɗin da aka kawo tare da tsayayyen wutar lantarki na DC.Idan adadin juyi ya ninka sau biyu to juriyar jujjuyawar ita ma za ta ninka (a cikin dogon nada) kuma ta haka za ta ragu da rabi.Tasirin yanar gizo ba karuwa a NI .

Abin da ke ƙayyade NI shine juriya kowane bi da bi.Don haka don ƙara NI kauri daga cikin waya dole ne a ƙara.Ƙimar ƙarin juyi shine cewa suna rage halin yanzu don haka wutar lantarki a cikin nada.

Mai zane ya kamata ya tuna cewa ma'aunin waya shine ainihin abin da ke ƙayyade ƙarfin maganadisu na nada.Wannan shine mafi mahimmancin siga na ƙirar coil.

Ana kiran samfurin NI a matsayin "ampere turns" na nada.

Juya Ampere Nawa ake Bukatar?

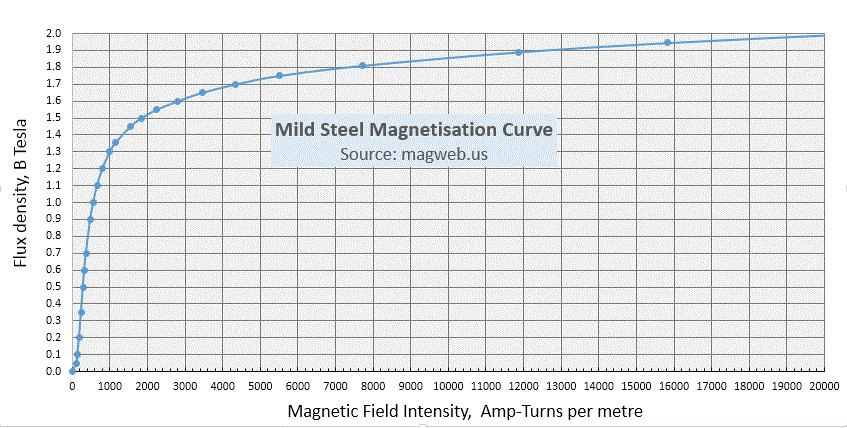

Karfe yana nuna jikewar maganadisu na kusan 2 Tesla kuma wannan yana saita ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙarfi kan yadda za a iya samun ƙarfi.

Daga cikin jadawali na sama mun ga cewa ƙarfin filin da ake buƙata don samun yawan juzu'i na 2 Tesla shine kusan 20,000 ampere-juya kowace mita.

Yanzu, don ƙirar Magnabend na yau da kullun, tsayin hanyar juyi a cikin ƙarfe yana kusan 1/5th na mita kuma saboda haka zai buƙaci (20,000/5) AT don samar da jikewa, wato kusan 4,000 AT.

Zai yi kyau a sami ƙarin jujjuyawar ampere da yawa fiye da wannan ta yadda za a iya kiyaye jikewar maganadisu ko da lokacin da aka gabatar da gibin da ba na maganadisu ba (watau kayan aikin da ba na ƙarfe ba) a cikin da'irar maganadisu.Duk da haka za a iya samun ƙarin juzu'in ampere a farashi mai yawa a cikin rarrabuwar wutar lantarki ko farashin wayar jan karfe, ko duka biyun.Don haka ana buƙatar sasantawa.

Tsarin Magnabend na yau da kullun yana da coil wanda ke samar da jujjuyawar ampere 3,800.

Lura cewa wannan adadi bai dogara da tsawon injin ɗin ba.Idan aka yi amfani da ƙirar maganadisu iri ɗaya akan kewayon tsayin injin to yana nuna cewa injunan da suka fi tsayi zasu sami ƙarancin juyawa na waya mai kauri.Za su zana ƙarin jimlar halin yanzu amma za su sami samfur iri ɗaya na juyawa na amps x kuma za su sami ƙarfi iri ɗaya (da wutar lantarki iri ɗaya) kowace raka'a tsawon tsayi.

Zagayen aiki

Manufar sake zagayowar aiki wani muhimmin al'amari ne na ƙirar lantarki.Idan ƙirar tana ba da ƙarin aikin sake zagayowar fiye da yadda ake buƙata to ba shi da kyau.Ƙarin sake zagayowar aiki a zahiri yana nufin cewa za a buƙaci ƙarin waya ta jan ƙarfe (tare da farashi mai girma) da/ko kuma za a sami ƙarancin matsawa.

Lura: Magnet na sake zagayowar aiki mafi girma zai sami ƙarancin wutar lantarki wanda ke nufin zai yi amfani da ƙarancin kuzari don haka ya zama mai rahusa don aiki.Koyaya, saboda maganadisu yana kunne na ɗan gajeren lokaci to ana ɗaukar farashin makamashin aiki a matsayin ɗan ƙaramin mahimmanci.Don haka tsarin ƙira shine samun ƙarancin wutar lantarki kamar yadda zaku iya tserewa cikin sharuddan rashin yin zafi da iska na nada.(Wannan hanya ta gama gari ga mafi yawan ƙirar electromagnet).

An ƙera Magnabend don sake zagayowar ayyuka na ƙima na kusan 25%.

Yawanci yana ɗaukar daƙiƙa 2 ko 3 kawai don yin lanƙwasa.Maganar maganadisu za ta kasance a kashe na tsawon daƙiƙa 8 zuwa 10 yayin da aka mayar da aikin aikin kuma an daidaita shi don lanƙwasawa na gaba.Idan an wuce 25% na sake zagayowar aiki to a ƙarshe magnet zai yi zafi sosai kuma nauyin zafi zai yi tafiya.Magnet ɗin ba zai lalace ba amma dole ne a bar shi ya yi sanyi na kusan mintuna 30 kafin a sake amfani da shi.

Kwarewar aiki tare da injuna a cikin filin ta nuna cewa 25% sake zagayowar aiki ya isa sosai ga masu amfani na yau da kullun.A haƙiƙa wasu masu amfani sun nemi nau'ikan nau'ikan wutar lantarki na zaɓi na na'ura waɗanda ke da ƙarin ƙarfi tare da ƙarancin sake zagayowar aiki.

Yanki Cross-Sectional Area

Yankin ƙetare da ke akwai don nada zai ƙayyade iyakar adadin waya na jan karfe wanda za'a iya sanyawa a ciki. Yankin da ake samuwa bai kamata ya zama fiye da yadda ake bukata ba, daidai da juyawa ampere da ake bukata da wutar lantarki.Samar da ƙarin sarari don nada zai ƙara girman maganadisu babu makawa kuma ya haifar da tsayin hanya mai tsayi a cikin ƙarfe (wanda zai rage jumullar juriyar).

Wannan gardamar tana nuna cewa duk abin da aka tanada a cikin ƙira ya kamata a cika shi da wayar tagulla.Idan bai cika ba to yana nufin cewa ma'aunin maganadisu zai iya zama mafi kyau.

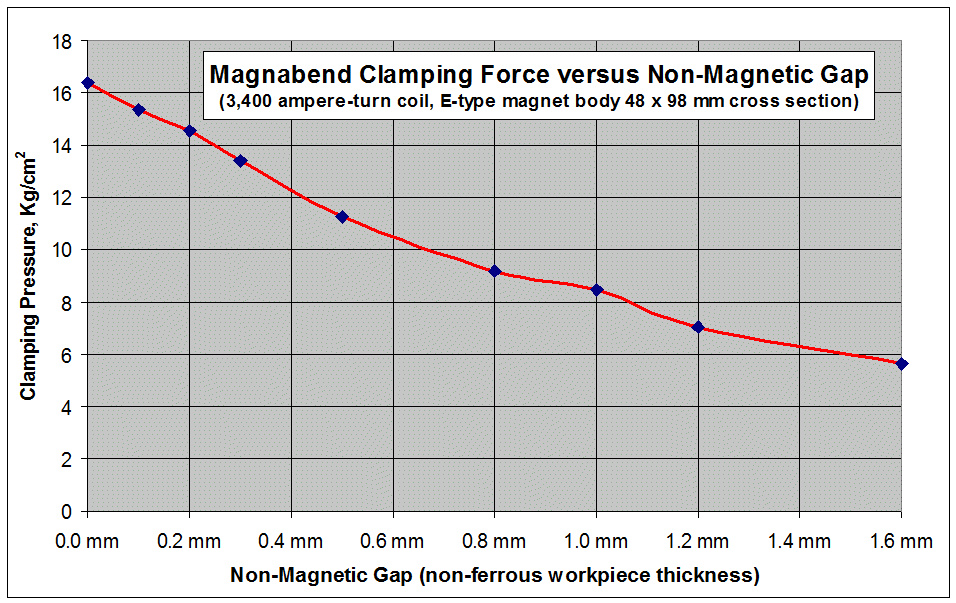

Magnabend Clamping Force:

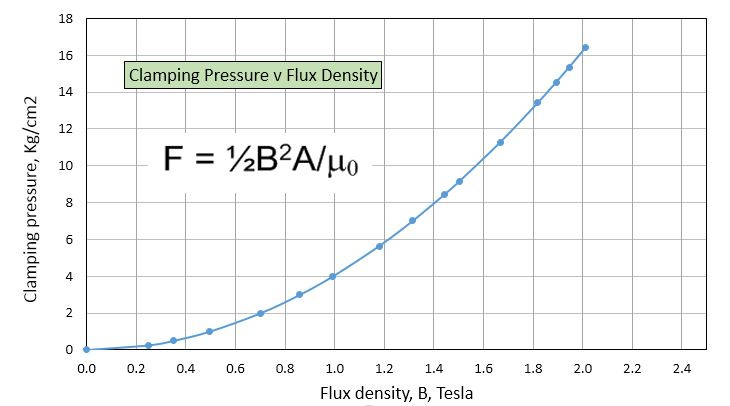

Hoton da ke ƙasa an samo shi ta ma'aunin gwaji, amma ya yarda daidai da ƙididdiga na ka'idoji.

Ana iya ƙididdige ƙarfin matsawa ta hanyar lissafi daga wannan dabara:

F = karfi a cikin Newtons

B = Girman jujjuyawar maganadisu a cikin Teslas

A = yanki na sanduna a cikin m2

µ0 = Magnetic permeability akai-akai, (4π x 10-7)

Misali za mu lissafta karfin matsawa don yawan juzu'i na 2 Tesla:

Ta haka F = ½ (2) 2 A/µ0

Domin karfi akan yanki naúrar (matsi) zamu iya sauke "A" a cikin dabara.

Don haka Matsi = 2/µ0 = 2/(4π x 10-7) N/m2.

Wannan yana fitowa zuwa 1,590,000 N/m2.

Don canza wannan zuwa ƙarfin kilogiram ana iya raba shi da g (9.81).

Don haka: Matsi = 162,080 kg / m2 = 16.2 kg / cm2.

Wannan ya dace da ma'aunin ƙarfin da aka auna don tazarar sifili da aka nuna akan jadawali na sama.

Ana iya juyar da wannan adadi cikin sauƙi zuwa jimlar ƙarfin maƙewa na na'ura ta hanyar ninka shi ta wurin sandar sandar na'ura.Don samfurin 1250E yankin sandar sandar shine 125 (1.4+3.0+1.5) = 735 cm2.

Don haka jimlar, sifili-rata, ƙarfi zai zama (735 x 16.2) = 11,900 kg ko 11.9 ton;kimanin tan 9.5 a kowace mita na tsayin maganadisu.

Yawan juzu'i da matsin lamba suna da alaƙa kai tsaye kuma ana nuna su a ƙasa:

Ƙarfin Ƙarfin Ƙarfin Ƙarfi:

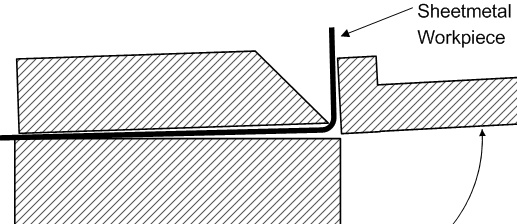

A aikace wannan babban ƙarfin matsawa yana samuwa ne kawai lokacin da ba a buƙata (!), Wato lokacin lanƙwasa kayan aikin ƙarfe na bakin ciki.Lokacin lankwasawa ba ferrous workpieces da karfi zai zama kasa kamar yadda aka nuna a cikin jadawali a sama, da kuma (kadan m), shi ma kasa lokacin lankwasa lokacin farin ciki workpieces karfe.Wannan saboda ƙarfin da ake buƙata don yin lanƙwasa mai kaifi ya fi wanda ake buƙata don lanƙwasa radius.Don haka abin da ke faruwa shi ne yayin da lanƙwasawa ke ci gaba da gefen gaba na clampbar yana ɗagawa kaɗan don haka ƙyale aikin aikin ya samar da radius.

Karamin tazarar iska wanda aka kafa yana haifar da ɗan asarar ƙarfi amma ƙarfin da ake buƙata don samar da lanƙwasa radius ya ragu sosai fiye da yadda ƙarfin maganadisu yake.Don haka tabbataccen yanayi yana haifar da clampbar baya barin tafiya.

Abin da aka bayyana a sama shi ne yanayin lanƙwasa lokacin da injin ɗin ke kusa da iyakar kauri.Idan an gwada aikin aikin da ya fi kauri to ba shakka clampbar zai tashi.

Wannan zane yana nuna cewa idan gefen hanci na clampbar ya ɗan yi haske, maimakon kaifi, to za a rage tazarar iska don lankwasa mai kauri.

Tabbas wannan shine lamarin kuma Magnabend da aka yi da kyau zai sami maƙalli tare da radiused baki.(Hanyar radiyo kuma ba ta da saurin lalacewa idan aka kwatanta da kaifi mai kaifi).

Ƙarƙashin Yanayin Lanƙwasawa:

Idan an yi ƙoƙarin lanƙwasa akan kayan aiki mai kauri sosai to injin ɗin ba zai tanƙwara shi ba saboda clampbar ɗin kawai zai tashi.(Abin sa'a wannan baya faruwa ta hanya mai ban mamaki; clampbar kawai yana barin tafiya cikin nutsuwa).

Koyaya idan nauyin lanƙwasawa ya ɗan fi ƙarfin lanƙwasawa na maganadisu to gabaɗaya abin da zai faru shine lanƙwasawa zai ci gaba da faɗi kusan digiri 60 sannan clampbar zai fara zamewa da baya.A cikin wannan yanayin gazawar maganadisu na iya tsayayya da nauyin lanƙwasawa a kaikaice ta hanyar ƙirƙirar juzu'i tsakanin kayan aikin da gadon maganadisu.

Bambancin kauri tsakanin gazawar saboda dagawa da gazawa saboda zamewar gabaɗaya baya da yawa.

Rashin haɓakawa ya faru ne saboda aikin aikin da ke ba da damar gefen gaba na ƙugiya zuwa sama.Ƙarfin matsawa a gefen gaba na clampbar shine galibi abin da ke ƙin wannan.Matsawa a gefen baya yana da ɗan tasiri saboda yana kusa da inda ake murzawa.A haƙiƙa rabin jimlar ƙarfin da ke ƙin ɗagawa ne kawai.

A gefe guda kuma ana yin tsayayya da zamiya da jimlar ƙulla ƙarfi amma ta hanyar gogayya don haka ainihin juriya ya dogara da ƙimar juriya tsakanin kayan aikin da saman maganadisu.

Don tsaftataccen ƙarfe da busassun ƙarfe madaidaicin juzu'i na iya zama sama da 0.8 amma idan lubrication yana nan to yana iya zama ƙasa da 0.2.Yawanci zai kasance wani wuri a tsakanin irin wannan yanayin rashin nasarar lanƙwasawa yawanci saboda zamewa ne, amma ƙoƙarin ƙara juzu'i a saman maganadisu an gano bai dace ba.

Ƙarfin kauri:

Don jikin maganadisu nau'in E mai faɗin 98mm da zurfin 48mm kuma tare da na'urar juyi mai juyi 3,800, cikakken ƙarfin lanƙwasawa shine 1.6mm.Wannan kauri ya shafi duka takardar karfe da takardar aluminum.Za a sami raguwar matsawa akan takardar aluminium amma yana buƙatar ƙarancin juzu'i don lanƙwasa shi don haka wannan yana ramawa ta yadda za a ba da ƙarfin ma'auni iri ɗaya na nau'ikan ƙarfe biyu.

Akwai buƙatun wasu fa'idodi akan iyawar lanƙwasawa da aka bayyana: Babban ɗayan shine ƙarfin da ake samu na ƙarfen takardar na iya bambanta ko'ina.Ƙarfin 1.6mm ya shafi karfe tare da yawan amfanin ƙasa har zuwa 250 MPa kuma zuwa aluminum tare da yawan amfanin ƙasa har zuwa 140 MPa.

Matsakaicin kauri a cikin bakin karfe shine kusan 1.0mm.Wannan ƙarfin yana da ƙasa da mahimmanci fiye da na sauran karafa saboda bakin karfe yawanci ba maganadisu bane amma duk da haka yana da ƙimar yawan amfanin ƙasa mai ma'ana.

Wani abu kuma shine zazzabi na maganadisu.Idan magnet ɗin ya ƙyale ya zama zafi to juriya na nada zai kasance mafi girma kuma wannan zai sa ya zana ƙarancin halin yanzu tare da ƙananan ampere-juyawa da ƙananan ƙarfi.(Wannan tasirin yawanci matsakaici ne kuma ba zai yuwu ya sa na'urar ta cika ƙayyadaddun ta ba).

A ƙarshe, ana iya yin mafi girman ƙarfin Magnabends idan sashin giciye na maganadisu ya fi girma.