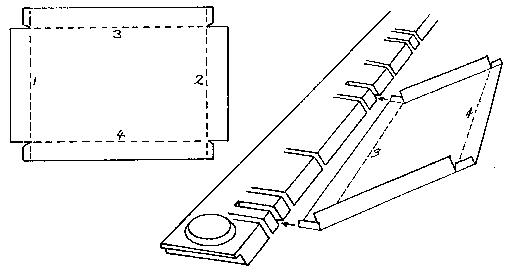

Matsakaicin Matsala: Na'urorin haɗi na Magnabend Sheetmetal Lankwasawa Injin

The Slotted Clampbar yana da kyau don yin tire marasa zurfi da kwanon rufi cikin sauri da daidai.

Fa'idodin matsi mai ramin ramuka akan saitin gajerun ƙugiya don yin tire shine cewa gefen lanƙwasawa yana daidaita ta atomatik zuwa sauran injin, kuma clampbar yana ɗagawa ta atomatik don sauƙaƙe shigarwa ko cire kayan aikin.(Kada-ƙasa, za a iya amfani da gajerun clampbars don samar da trays na zurfi marar iyaka, kuma ba shakka, sun fi kyau don yin hadaddun siffofi.)

A cikin amfani, ramukan suna daidai da raƙuman da aka bari tsakanin yatsan akwati na al'ada & injin nadawa.Nisa na ramummuka shine yadda kowane ramummuka guda biyu zasu dace da tire akan girman girman 10 mm, kuma lamba da wuraren ramukan sun kasance kamar kowane girman tire, koyaushe ana iya samun ramuka biyu waɗanda zasu dace da shi. .

| Tsawon matsi mai ramin rami | Suits model | Siffofin trays na tsayi | Mafi girman zurfin tire |

| mm 690 | 650E | 15 zuwa 635 mm | 40 mm |

| 1070 mm | 1000E | 15 zuwa 1015 mm | 40 mm |

| 1320 mm | 1250E, 2000E, 2500E & 3200E | 15 zuwa 1265 mm | 40 mm |

Don ninka tire mai zurfi:

Ninka farkon bangarorin biyu gaba da juna da shafukan kusurwa ta amfani da matsi mai ramin ramuka amma yin watsi da kasancewar ramukan.Waɗannan ramummuka ba za su sami wani tasiri mai fa'ida akan folds ɗin da aka gama ba.

Yanzu zaɓi ramummuka biyu tsakanin waɗanda za a ninka saura bangarorin biyu.Wannan hakika yana da sauqi kuma abin mamaki cikin sauri.Kawai jera gefen hagu na tiren ɓangarorin da aka yi tare da mafi yawan ramin hagu kuma duba idan akwai ramin gefen dama don turawa cikin;in ba haka ba, zame tiren tare har sai gefen hagu ya kasance a ramin na gaba kuma a sake gwadawa.Yawanci, yana ɗaukar kusan 4 irin waɗannan ƙoƙarin don nemo ramummuka biyu masu dacewa.

A ƙarshe, tare da gefen tire a ƙarƙashin madaidaicin kuma tsakanin ramukan da aka zaɓa, ninka sauran bangarorin.Bangarorin da aka kafa a baya suna shiga cikin zaɓaɓɓun ramummuka yayin da aka kammala folds na ƙarshe.

Lokacin aikawa: Satumba-23-2022