Sau da yawa mutane suna tambayata in duba lissafinsu don ƙirar coil "Magnabend".Wannan ya sa ni fito da wannan shafin yanar gizon wanda ke ba da damar yin lissafin atomatik da zarar an shigar da wasu bayanan asali.

Godiya da yawa ga abokin aikina, Tony Grainger, don shirin JavaScript wanda ke yin lissafin akan wannan shafin.

SHIRIN KALKULATOR

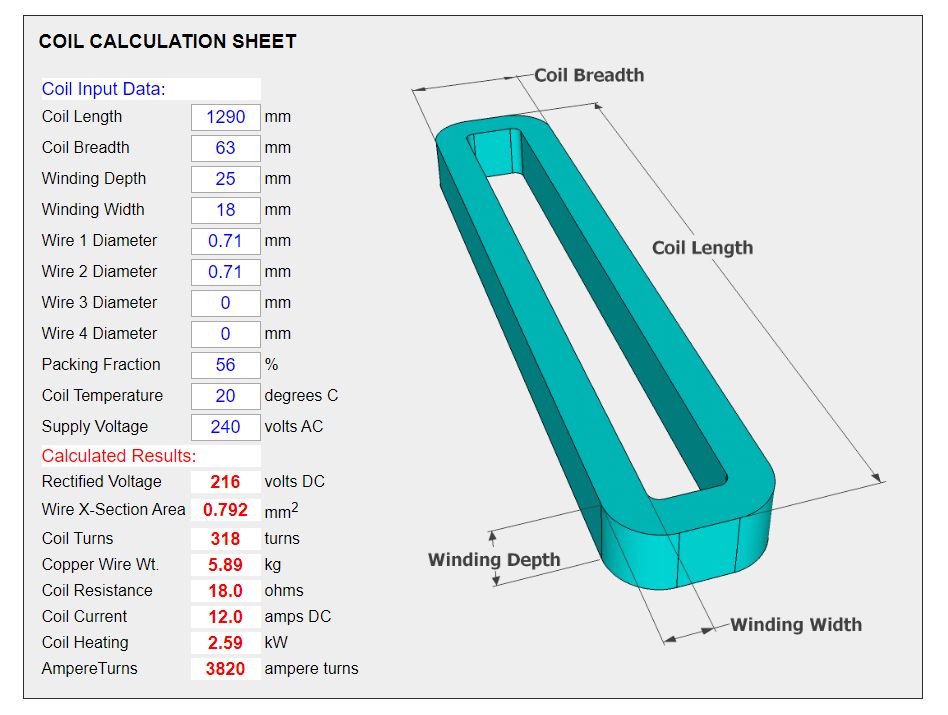

Takardar lissafin da ke ƙasa an ƙirƙira shi ne don coils na "Magnabend" amma zai yi aiki ga kowane nau'in maganadisu wanda ke aiki daga ingantacciyar wutar lantarki (DC).

Don amfani da takardar lissafin kawai danna a cikin filayen shigar da bayanan Coil kuma a rubuta a cikin girman coil ɗinku da girman waya.

Shirin yana sabunta sashin Sakamakon Lissafi duk lokacin da ka danna ENTER ko danna wani filin shigarwa.

Wannan yana sa ya zama mai sauri da sauƙi don duba ƙirar coil ko gwada sabon ƙirar naɗa.

Lambobin da aka riga aka cika a cikin filayen bayanan shigarwa misali ne kawai kuma lambobi ne na yau da kullun don babban fayil na 1250E Magnabend.

Maye gurbin lambobi misali tare da bayanan coil ɗin ku.Lambobin misalin za su koma cikin takardar idan kun sabunta shafin.

(Idan kuna son adana bayanan ku to Ajiye ko Buga shafin kafin ku sabunta shi).

Tsare-tsaren Zane-zanen Coil:

Shigar da ma'auni don ƙirar coil ɗin da kuka yi niyyar samarwa, da ƙarfin wutar lantarki da kuke so.(Misali 110, 220, 240, 380, 415 Volts AC)

Saita Waya 2, 3 da 4 zuwa sifili sa'an nan kuma kimanta ƙimar diamita na Wire1 kuma lura da yawan sakamakon AmpereTurns.

Daidaita diamita na Wire1 har sai an cimma burin AmpereTurns, faɗi game da 3,500 zuwa 4,000 AmpereTurns.

A madadin za ku iya saita Wire1 zuwa girman da aka fi so sannan ku daidaita Wire2 don cimma burin ku, ko saita duka Wire1 da Wire2 zuwa mafi girman girma sannan ku daidaita Wire3 don cimma burin ku da dai sauransu.

Yanzu ku duba Duminar Coil Heating (ƙarar wutar lantarki)*.Idan ya yi tsayi da yawa (ka ce fiye da 2 kW a kowace mita na tsawon coil) to AmpereTurns zai buƙaci a rage.A madadin haka za'a iya ƙara ƙarin jujjuyawar a cikin nada don rage halin yanzu.Shirin zai ƙara ƙarin juyi ta atomatik idan kun ƙara nisa ko zurfin nada, ko kuma idan kun ƙara juzu'in Packing.

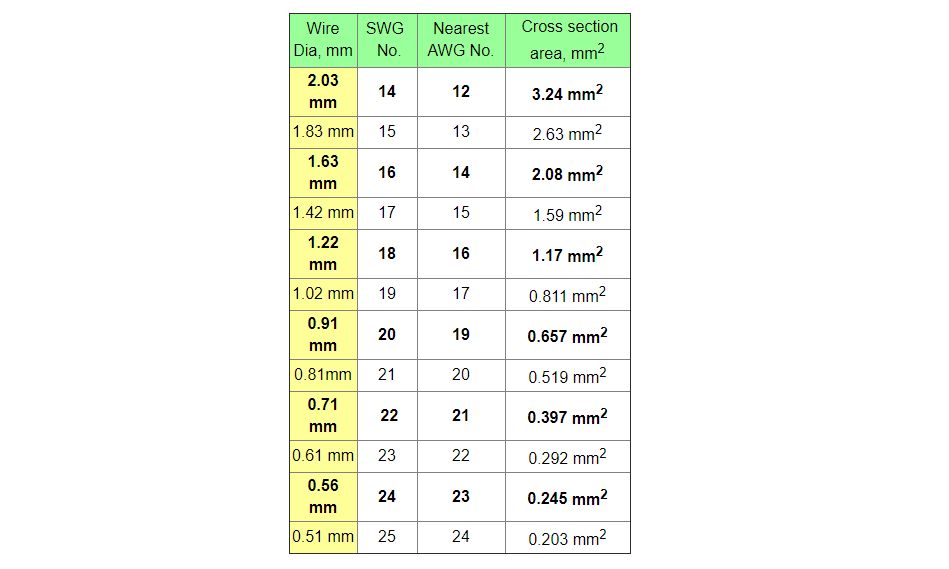

A ƙarshe tuntuɓi tebur na daidaitattun ma'aunin waya kuma zaɓi waya, ko wayoyi, waɗanda ke da yanki mai haɗaɗɗiyar yanki daidai da ƙimar da aka lissafta a mataki na 3.

* Lura cewa lalata wutar lantarki yana da hankali sosai ga AmpereTurns.Tasirin dokar murabba'i ce.Misali idan kun ninka AmpereTurns sau biyu (ba tare da haɓaka sararin samaniya ba) to bacewar wutar lantarki zai ƙaru da sau 4!

Ƙarin AmpereTurns yana ƙaddamar da waya mai kauri (ko wayoyi), kuma waya mai kauri yana nufin ƙarin wutar lantarki na yanzu da mafi girma sai dai idan ana iya ƙara adadin juyi don ramawa.Kuma ƙarin jujjuyawar yana nufin babban nada da/ko mafi kyawun juzu'in tattarawa.

Wannan Shirin Lissafi na Coil yana ba ku damar gwaji tare da duk waɗannan abubuwan cikin sauƙi.

BAYANI:

(1) Girman waya

Shirin yana ba da har zuwa wayoyi 4 a cikin coil.Idan ka shigar da diamita na waya fiye da ɗaya to shirin zai ɗauka cewa duk wayoyi za su yi rauni tare kamar waya ɗaya kuma an haɗa su a farkon da kuma ƙarshen iska.(Wato wayoyi na lantarki a layi daya).

(Domin wayoyi 2 ana kiran wannan bifilar winding, ko na wayoyi 3 trifilar winding).

(2) Juzu'in tattarawa, wani lokaci ana kiransa da cika abubuwa, yana bayyana adadin yawan iskar da aka shagaltar da wayar tagulla.Siffar wayar ta shafa (yawanci zagaye), kaurin rufin da ke kan waya, kauri na murfin murfin murɗa na waje (yawanci takarda lantarki), da kuma hanyar iska.Hanyar iska na iya haɗawa da jumble winding (wanda ake kira winding na daji) da kuma iska.

Don jumble-rauni juzu'in juzu'i zai kasance a cikin kewayon 55% zuwa 60%.

(3) Ƙarfin Coil wanda aka samo daga lambobi misali da aka riga aka cika (duba sama) shine 2.6 kW.Wannan adadi na iya zama kamar babba amma an ƙididdige injin Magnabend don sake zagayowar aikin kusan kashi 25%.Don haka ta fuskoki da yawa ya fi dacewa a yi tunanin matsakaicin wutar lantarki wanda, dangane da yadda ake amfani da injin, zai zama kashi ɗaya bisa huɗu na wannan adadi, yawanci ma ƙasa da haka.

Idan kuna desiging daga karce to gaba ɗaya watsawar wutar lantarki shine madaidaicin shigo da kaya don la'akari;idan yayi tsayi da yawa to kwandon zai yi zafi kuma zai iya lalacewa.

An ƙera injinan Magnabend tare da lalata wutar lantarki kusan 2kW kowace mita na tsayi.Tare da sake zagayowar aikin 25% wannan yana fassara zuwa kusan 500W kowace mita na tsayi.

Yadda zafin magnet zai samu ya dogara da abubuwa da yawa ban da zagayowar aiki.Da fari dai rashin kuzari na magnet, da duk abin da yake hulɗa da shi, (misali tsayawa) yana nufin cewa dumama kai zai kasance a hankali.Tsawon lokaci mai tsawo za a rinjayi zafin maganadisu ta yanayin yanayin yanayi, sararin saman maganadisu har ma da wane launi aka zana shi!(Misali launin baƙar fata yana haskaka zafi fiye da launin azurfa).

Hakanan, idan aka ɗauka cewa maganadisu wani ɓangare ne na injin "Magnabend", to kayan aikin da ake lanƙwasa za su ɗauki zafi yayin da suke danne a cikin magnet kuma ta haka za su ɗauke wani zafi.A kowane hali yakamata a kiyaye maganadisu ta na'urar tafiya mai zafi.

(4) Lura cewa shirin yana ba ku damar shigar da zafin jiki don na'urar kuma ta haka za ku iya ganin tasirinsa akan juriya na coil da na'urar yanzu.Domin waya mai zafi tana da juriya mafi girma sannan yana haifar da raguwar coil current kuma saboda haka kuma ya rage ƙarfin maganadisu (AmpereTurns).Tasirin yana da mahimmanci.

(5) Shirin ya ɗauka cewa an raunata coil ɗin da wayar tagulla, wanda shine nau'in waya mafi amfani ga na'urar maganadisu.

Wayar Aluminum kuma abu ne mai yuwuwa, amma aluminum yana da tsayayya fiye da jan ƙarfe (mita 2.65 ohm idan aka kwatanta da 1.72 don jan karfe) wanda ke haifar da ƙira mara inganci.Idan kuna buƙatar lissafin waya na aluminum to don Allah a tuntube ni.

(6) Idan kuna zayyana coil don babban fayil ɗin ƙarfe na "Magnabend", kuma idan jikin magnet ɗin yana da daidaitaccen girman sashin giciye (ce 100 x 50mm) to tabbas yakamata kuyi nufin ƙarfin maganadisu (AmpereTurns) na kusa. 3,500 zuwa 4,000 ampere juya.Wannan adadi ya kasance mai zaman kansa daga ainihin tsawon injin.Dogayen injuna za su buƙaci amfani da waya mai kauri (ko ƙarin igiyoyin waya) don cimma wannan ƙimar ga AmpereTurns.

Ko da ƙarin jujjuyawar ampere zai fi kyau, musamman idan kuna son ɗaukar kayan da ba na maganadisu ba kamar aluminum.

Koyaya, don girman girman maganadisu da kauri na sanduna, ƙarin jujjuyawar ampere za a iya samu ne kawai a cikin kuɗin mafi girma na halin yanzu kuma don haka haɓakar wutar lantarki kuma sakamakon haɓakar dumama a cikin maganadisu.Wannan yana iya zama OK idan ƙananan aikin sake zagayowar yana da karɓa idan ba haka ba ana buƙatar babban filin iska don ɗaukar ƙarin juyi, kuma wannan yana nufin babban maganadisu (ko sandunan bakin ciki).

(7) Idan kuna zayyana, ku ce, Magnetic chuck to za a buƙaci zagayowar aiki mafi girma.(Ya danganta da aikace-aikacen to ana iya buƙatar sake zagayowar aiki 100%).A wannan yanayin za ku yi amfani da waya mafi sira da ƙila ƙila ƙira don ƙarfin maganadisu na faɗin ampere 1,000.

Bayanan kula na sama kawai don ba da ra'ayi ne na abin da za a iya yi tare da wannan tsarin ƙididdiga mai jujjuyawa.

Daidaitaccen Ma'aunin Waya:

An auna girman waya ta tarihi a ɗayan tsarin biyu:

Standard Wire Gauge (SWG) ko American Wire Gauge (AWG)

Abin baƙin ciki shine lambobin ma'aunin waɗannan ma'auni guda biyu ba su yi daidai da juna ba kuma hakan ya haifar da rudani.

A zamanin yau yana da kyau a yi watsi da waɗannan tsoffin ƙa'idodi kuma kawai koma zuwa waya ta diamita a cikin millimeters.

Anan akwai tebur masu girma dabam wanda zai ƙunshi kowace waya da wataƙila ana buƙata don naɗaɗɗen maganadisu.

Girman waya a nau'in m shine mafi yawan abubuwan da aka adana don haka zai fi dacewa zaɓi ɗayan waɗannan.

Misali Badger Wire, NSW, Ostiraliya tana da girma masu zuwa a cikin waya ta jan karfe da aka rufe:

0.56, 0.71, 0.91, 1.22, 1.63, 2.03, 2.6, 3.2 mm.

Da fatan za a tuntube ni da kowace tambaya ko sharhi.

Lokacin aikawa: Oktoba-12-2022